- Home

- About Us

-

Our Products

-

Ball Plunger M.S.& S.S. SP..

-

Pin Plunger S.S. SP-02

-

Index Plunger M.S& S.S. SP..

-

Index Plunger M.S& S.S. SP..

-

L Indexing Plunger SP-07

-

Screw Fit Plunger SP-08

-

Press Fit Plunger SP-09

-

S.S. Press Fit Plunger SP.09-B

-

Indexing Plunger SP-11

-

Ball Spring Plungers SP-01

-

Pin Plungers SP-02

-

Index Plungers SP-06

-

M.S.& S.S. Hinges HS-42

-

M.S.& S.S Concealed HS-43

-

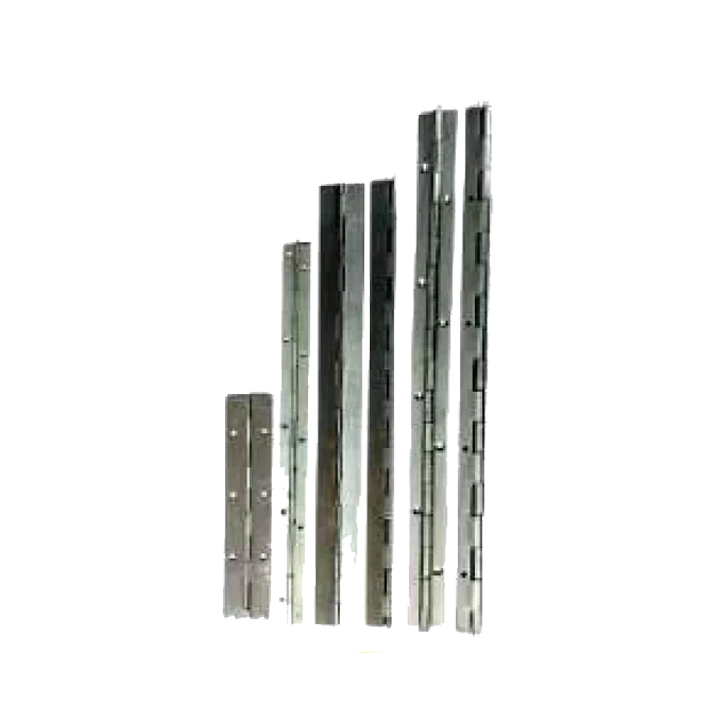

S.S.304 Piano Hinges HS-44

-

Metal Hinges HS-45

-

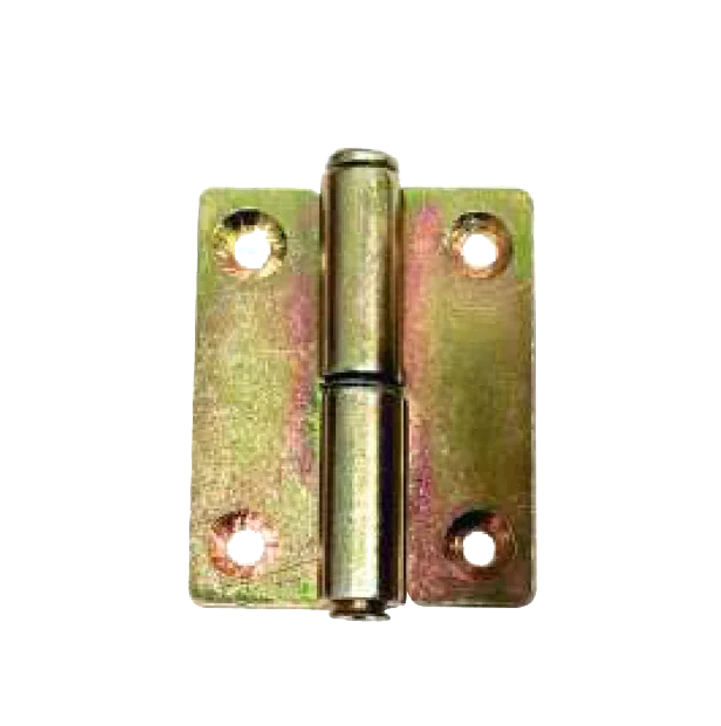

M.S. Hinges HS-52

-

S.S. 5036 HS-53

-

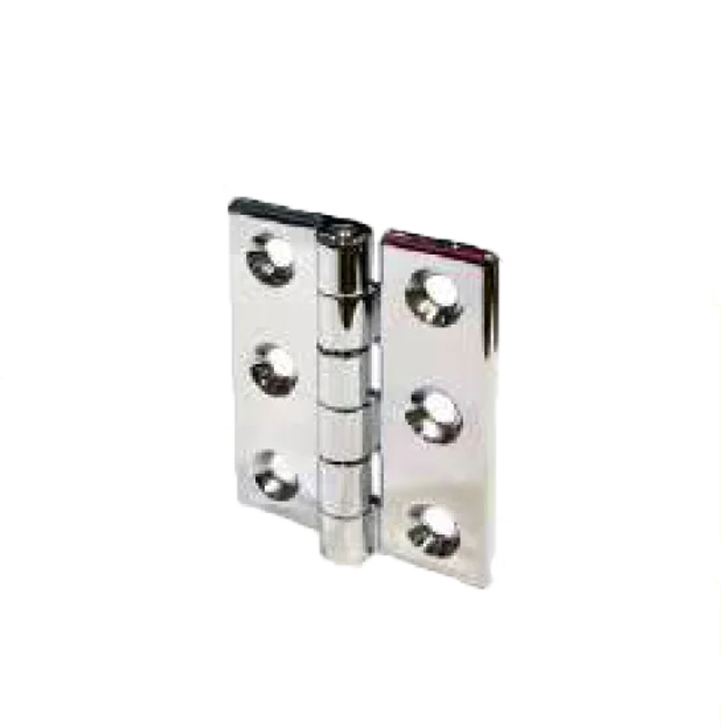

S.S. Hinges HS-54 N

-

Poly 98*70 HS-57 N

-

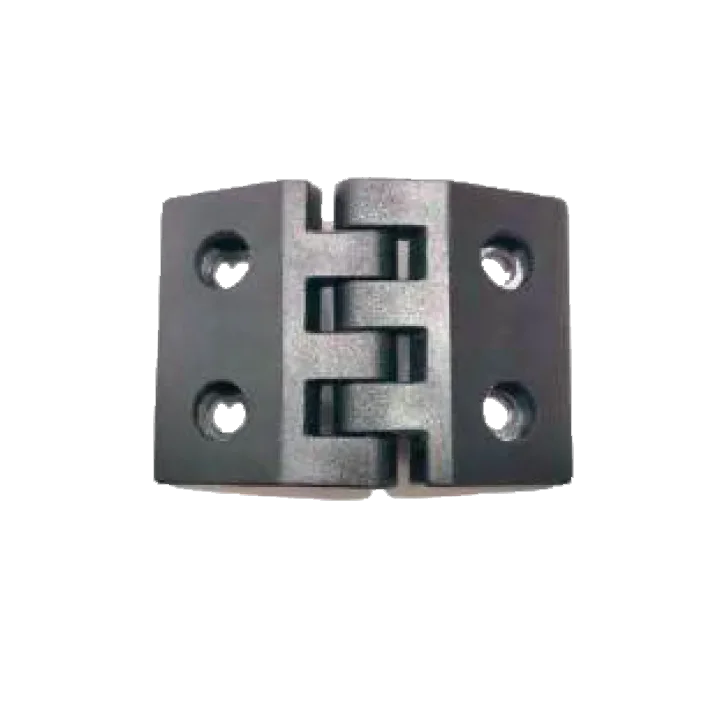

Die-Cast 60*49 HS-68 N

-

Die-Cast 50*40 HS-69 N

-

Die-Cast 54*40 Bolted HS-70 N

-

Damper Hinge 30mm HS-71 N

-

Damper Hinge 50mm HS-72 N

-

Bent Right Angle Hinge HS-73 N

-

DC Positioning Hinge HS-74 N

-

Brass 65*50 HS-75 N

-

Poly 92 HL-01

-

Poly 120 HL-02

-

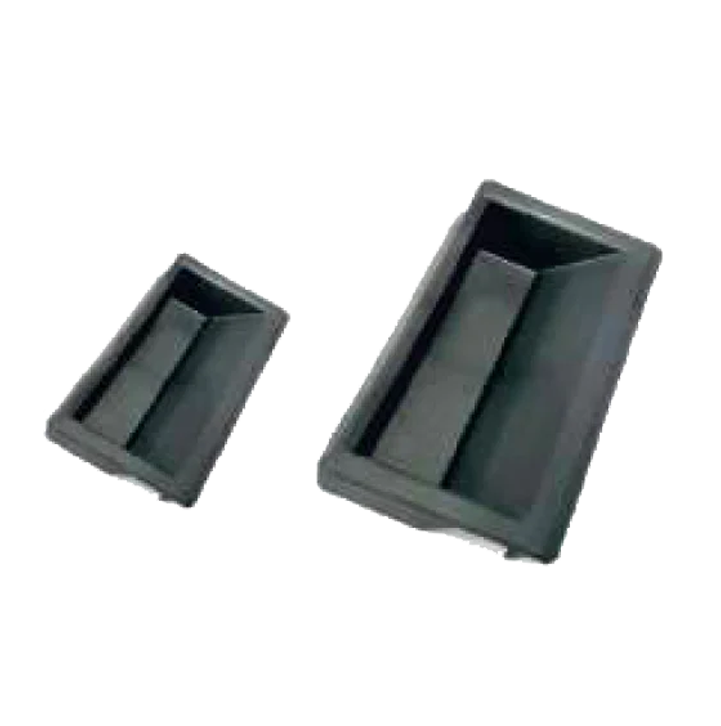

Pocket Handle HL-05

-

Pocket Handle HL-05-B

-

Die-Cast Adjustable HL-08

-

Polyamide Crank HL-11-A

-

Poly Revolving Handle HL-12-A

-

Curved Revolving Handle

-

M.S. Revolving Handle HL-12-C

-

Metal Revolving Handle HL-12-E

-

Pipe Handle HL-13-B

-

Pipe Handle HL-14

-

Poly HL-15

-

Poly HL-16

-

U-Handle Folding HL-17

-

U-Handle Folding HL-19

-

M.S. Handle HL-25

-

Poly Handle HL-20

-

Strap Handle HL-21

-

Pipe Handle HL-22

-

Pipe Handle HL-23

-

A.B.S. Handle HL-24

-

Poly HL-03

-

Polyamide Adjustable HL-09

-

Polyamide Crank HL-11-B

-

Revolving Handle HL-12-D

-

Pipe Handle HL-13-A

-

Little Bracket 150mm CR-101

-

Little Bracket 165mm CR-102

-

Little Bracket 195mm CR-103

-

Side Bracket 245mm CR-104

-

Swivel Bracket 245mm CR-105

-

Side Bracket 228mm CR-106

-

Single Clamp CR-109

-

Double Clamp 40mm CR-112

-

Double Clamp 68mm CR-113

-

Single Clamp M6 CR-114

-

Single Rod Guide CR-121

-

Drip Tray Holder CR-122

-

Metal Leveling Pad MLP-05

-

Leveling Pad M.S.& S.S. LP..

-

Leveling Pad M.S.& S.S. LP..

-

Leveling Pad M.S.& S.S. LP..

-

Leveling Pad M.S.& S.S. LP..

-

M.S.& S.S. Leveling Pad ML..

-

M.S.& S.S. Leveling Pad ML..

-

M.S. Leveling Pad MLP-03

-

S.S.304 Leveling Pad MLP-04

-

Foot Mount M.S. FM-01

-

Foot Mount M.S. FM-02

-

Foot Mount M.S.& S.S. FM-0..

-

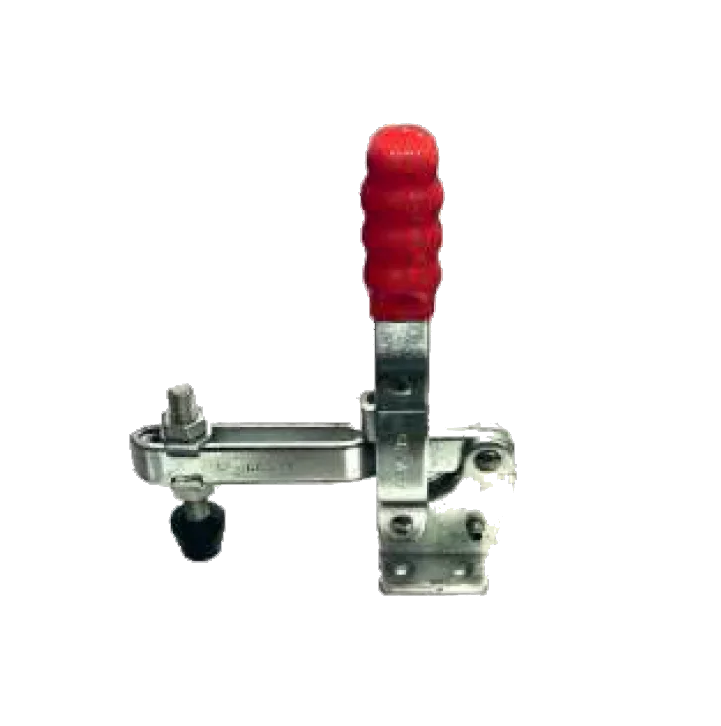

Clamp 90mm M S S S CL-01-A

-

Clamp 102mm M S S S CL-01-B

-

Clamp 54mm M S S S CL-02-A

-

Clamp 54mm M S S S CL-02-B

-

Clamp 100mm M S S S CL-03

-

Clamp 100mm M S S S CL-04

-

Clamp 125mm M S CL-05

-

Clamp M S S S CL-06

-

Clamp M S S S CL-07

-

Spring Clamp M S S S CL-08-A

-

Spring Clamp M S S S CL-08-B

-

Clamp 110mm M S S S CL-09

-

Spring Clamp M S S S CL-11

-

Spring Clamp M S S S CL-12-A

-

Spring Clamp M S S S CL-12-B

-

Small Clamp M S S S CL-13

-

Die-Cast Lift Off HS-01

-

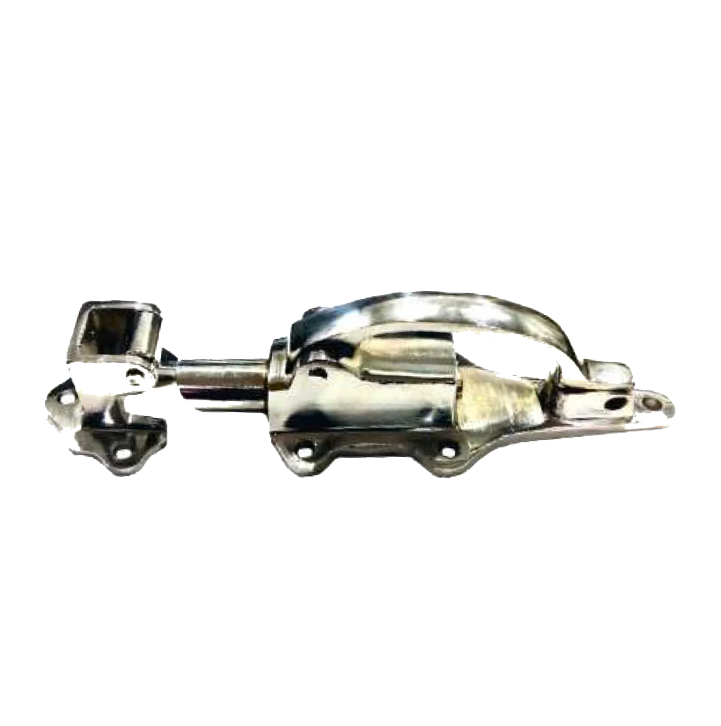

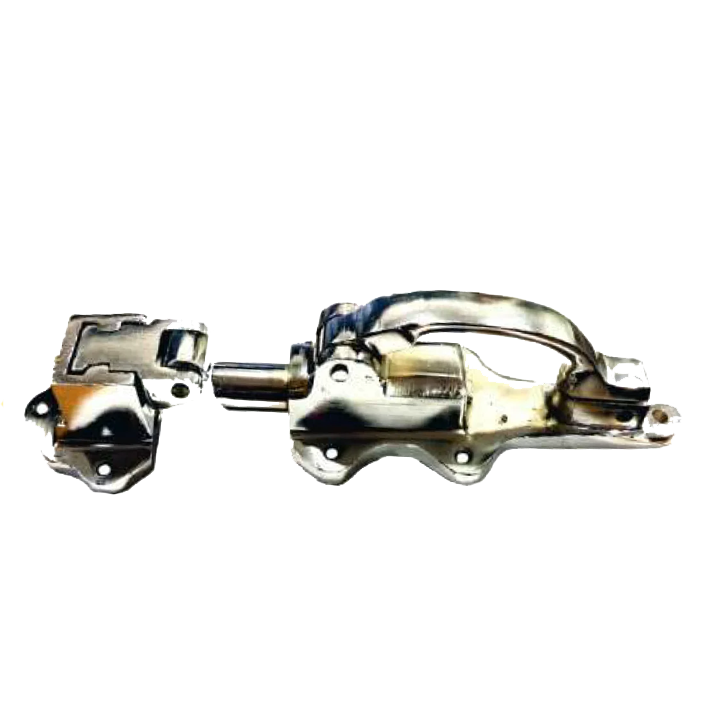

M S Siemens HS-02-A

-

M S Siemens HS-02-B

-

M S Siemens HS-02-C

-

M S Siemens HS-03

-

M S Lift Off HS-04

-

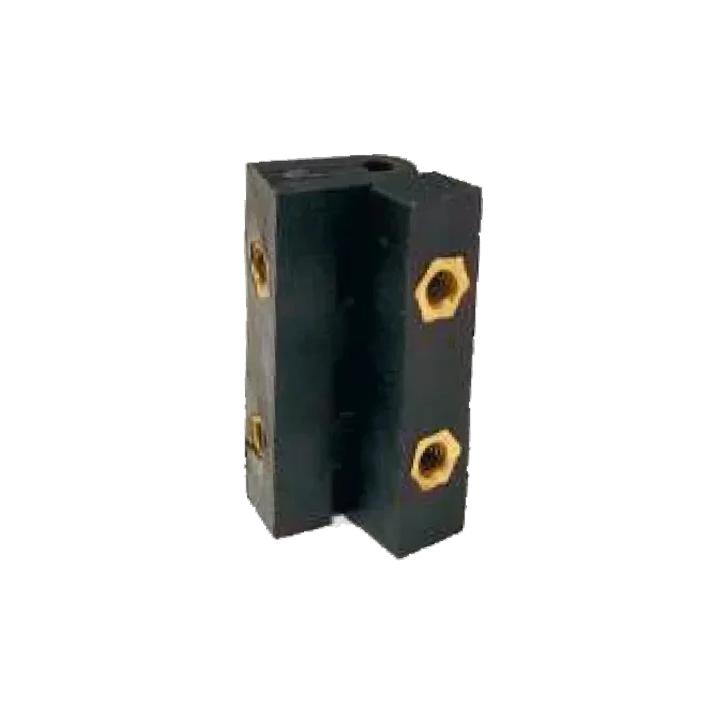

M S Consealed HS-06-A

-

M S Consealed HS-06-B

-

M S S S Consealed HS-07

-

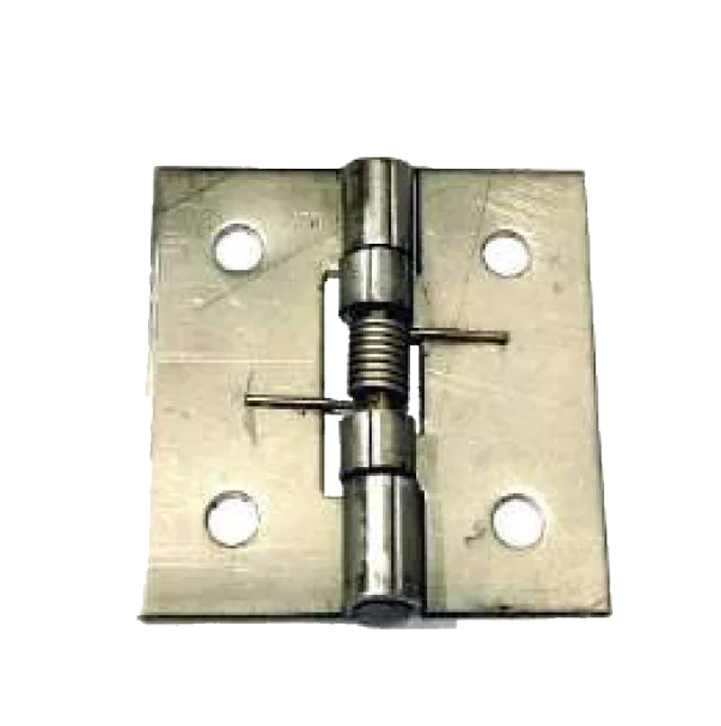

Spring Type S S M S HS-08

-

Spring Type HS-09

-

L T M S S S HS-10

-

S S Spring HS-11

-

Capsule-Type S S M S HS-12

-

L T M S S S HS-13

-

Z-TYPE HS-13-Z

-

Poly Profile HS-25

-

Poly 7048/4530 HS-26

-

Poly 4048/ 2630 HS-50

-

Poly 3048/ 1230 HS-51

-

Poly 5070 HS-27

-

Poly 4849 HS-28

-

Die-Cast S.S. 4 Hole HS-30

-

Die-Cast 50*63

-

Die-Cast 50*76

-

Die-Cast Bolted HS-31-A

-

Die-Cast HS-21-B

-

Die-Cast Rittal HS-32-A

-

Mild Steel Rittal HS-32-B

-

Polyamide 046 HS-33

-

Poly 4 Hole

-

M.S.& S.S. Hinges HS-38

-

Die Cast Hinges HS-62

-

M.S. Hinges HS-37

-

MS & S.S. Hinges HS-35

-

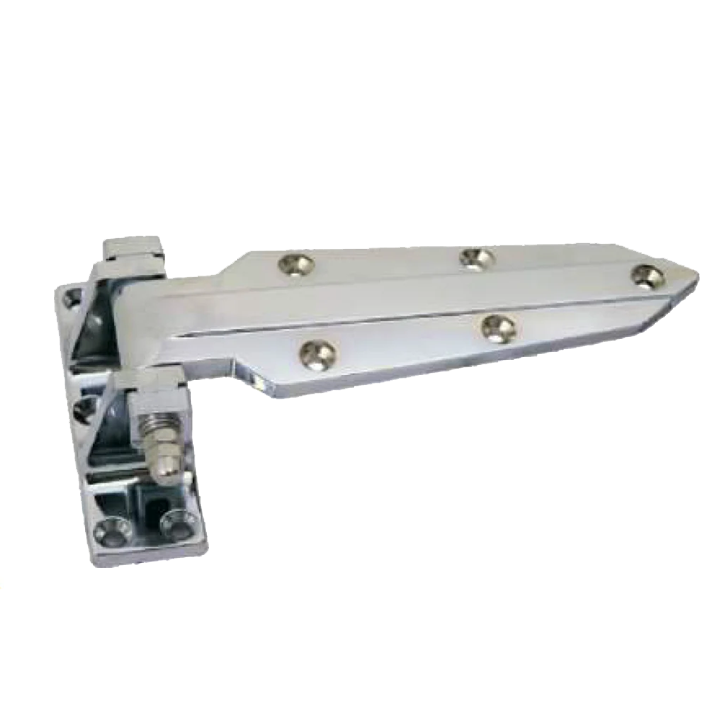

S.S. Lift Off Hinges

-

S.S. Butt Hinges HS-40-B

-

M.S.& S.S. Hinges HS-41

-

Conveyor Guide

-

Conveyor Clamps

-

Support Base CR-201

-

Support Base CR-202

-

Support Base CR-203

-

Drip Tray Supports CR.252

-

Fixing Washer CR.338

-

Clamp For Sensor CR.341

-

Connecting Joints CR.501

-

Support Head CR-502-A

-

Support Head CR-502-B

-

Side Mounting Bracket CR.513

-

Round Tube Ends CR.708

-

Square Tube Ends CR.710

-

- Our Gallery

- Our Blog

- Contact Us

-