The Role of Industrial Components Manufacturers in Modern Industries

Author / Date: 01 Sep, 2025

Efficiency, precision and reliability are the keys to success in the modern high-speed manufacturing ecosystem. The core of this change is a cluster of experts that are mostly ignored but very important- Industrial Components Manufacturers. These companies deliver the building blocks that drive industrial growth in every part of the world with complex control panel accessories that keep electrical processes running smoothly and powerful solutions that are provided by conveyor parts manufacturers.

This blog explains why industrial components are essential, how they are used, why specialized manufacturers play a significant role, and why any business needs them to succeed.

Understanding the Role of Industrial Components Manufacturers

Efficiency, precision and reliability are the keys to success in the modern high-speed manufacturing ecosystem. The core of this change is a cluster of experts that are mostly ignored but very important- Industrial Components Manufacturers. These companies deliver the building blocks that drive industrial growth in every part of the world with complex control panel accessories that keep electrical processes running smoothly and powerful solutions that are provided by conveyor parts manufacturers.

This blog explains why industrial components are essential, how they are used, why specialized manufacturers play a significant role, and why any business needs them to succeed.

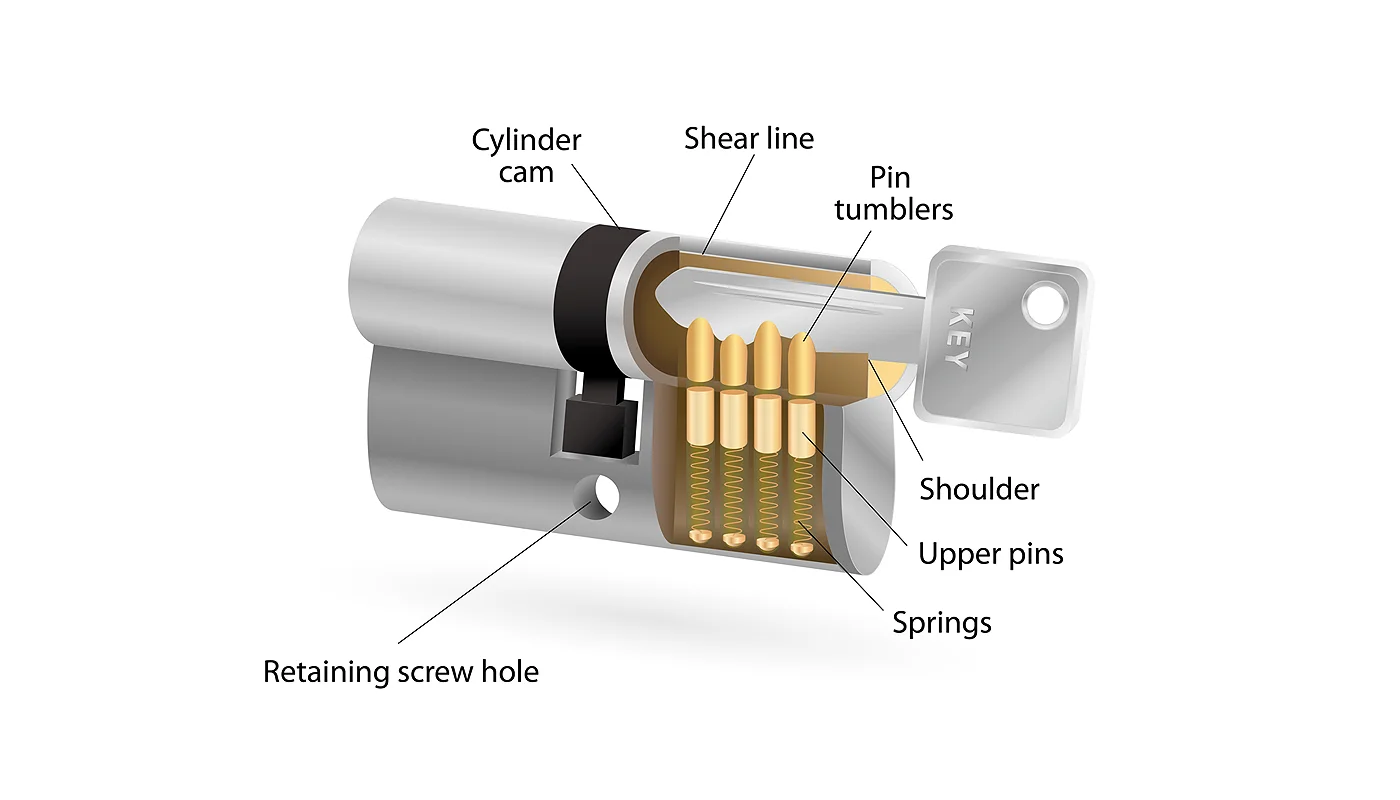

Control Panel Accessories: Powering Precision and Safety

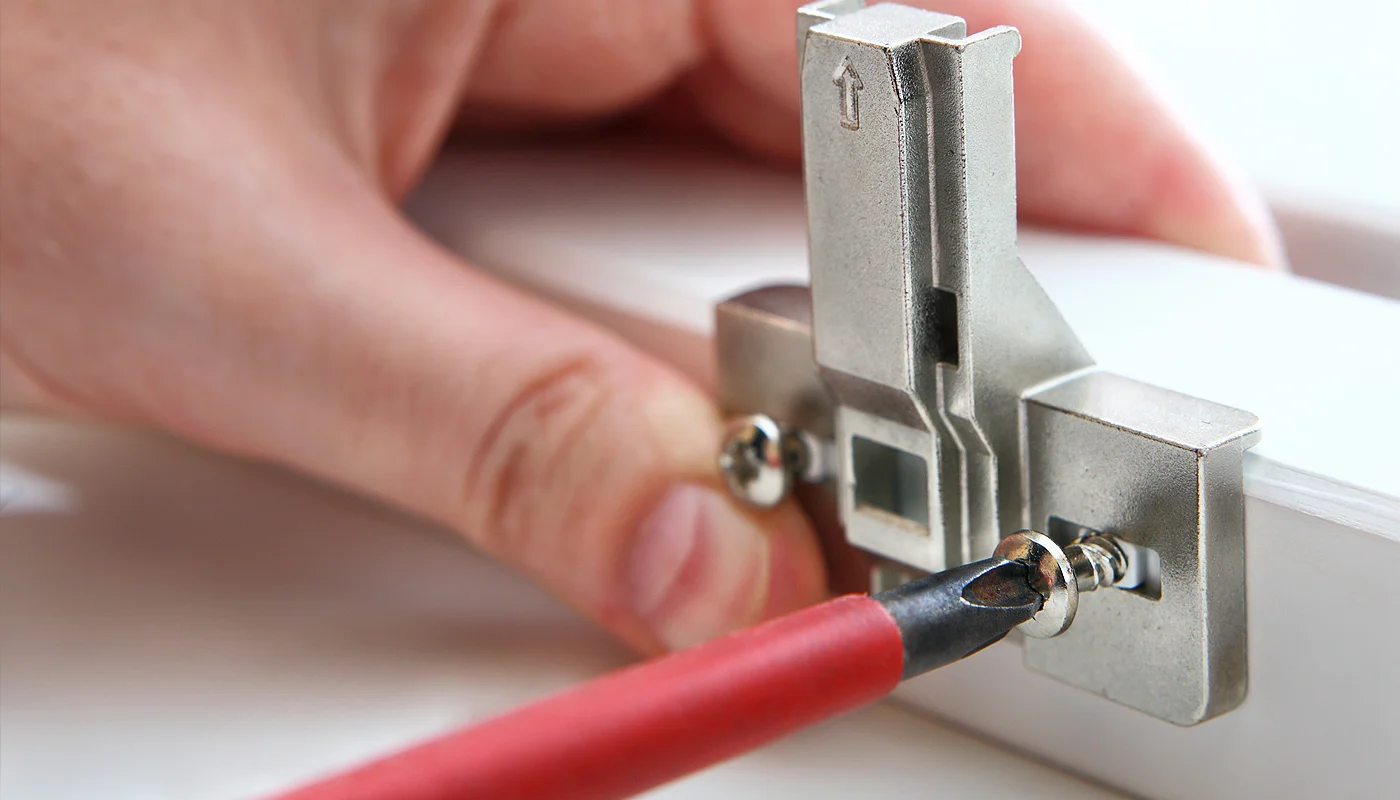

A major segment within industrial components is control panel accessories. These are crucial for electrical and automation systems, as they keep power distribution safe, efficient, and organized.

Some common control panel accessories include:

-

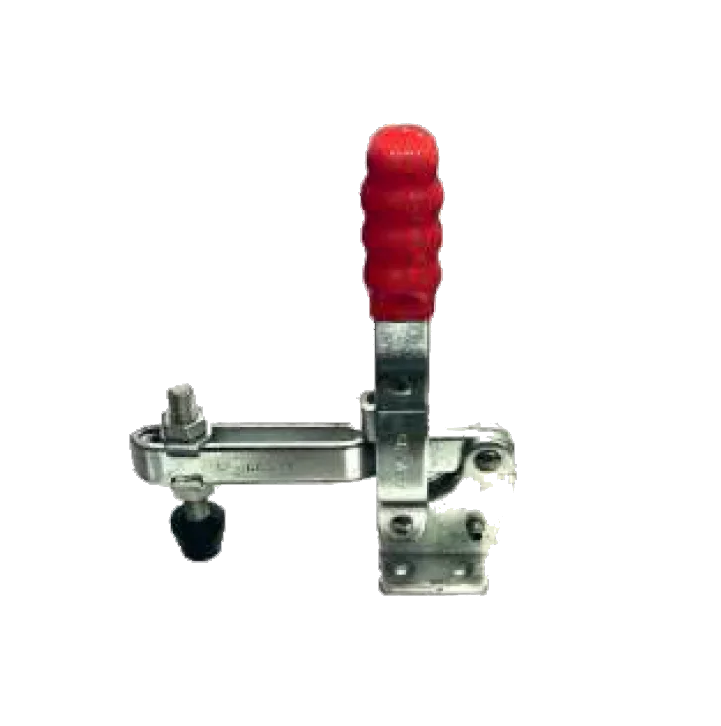

Panel locks and latches – for securing electrical enclosures.

-

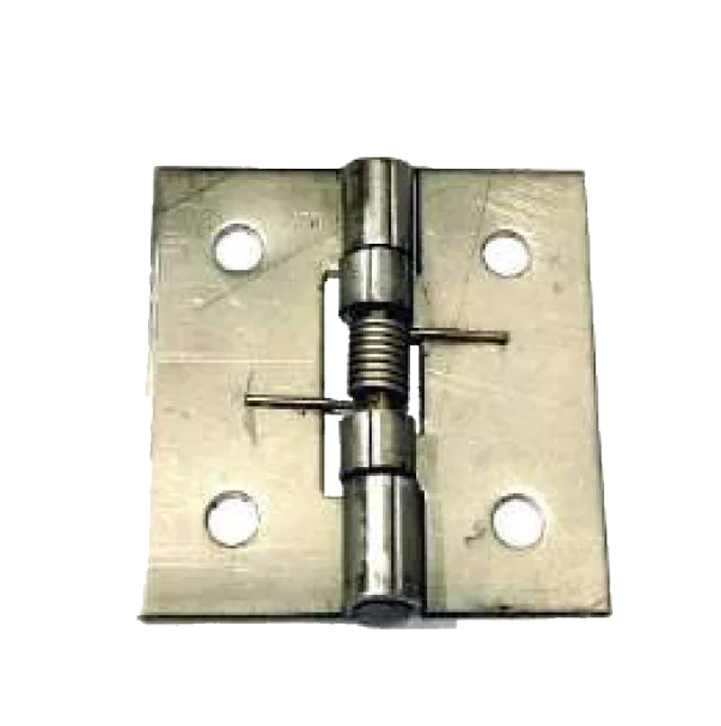

Flat hinges and handles – to enable smooth access to control systems.

-

Cable management systems – for organized wiring and reduced hazards.

-

Cooling systems and fans – to prevent overheating of panels.

-

Indicator lights and switches – to monitor and control machinery.

These accessories may look small, but their impact is significant. For example, without a secure locking system, an electrical panel could be exposed to dust, water, or unauthorized access, leading to operational risks.

Industrial components manufacturers specializing in control panel accessories play a pivotal role in helping businesses maintain compliance with international safety standards while ensuring ease of operation.

Conveyor Parts Manufacturers: Supporting Material Handling Efficiency

Another vital area of industrial components is conveyor parts. Modern industries rely heavily on conveyor systems for smooth material handling, especially in logistics, automotive, packaging, and food processing sectors.

Conveyor parts manufacturers produce components such as:

-

Conveyor rollers – for the smooth movement of goods.

-

Side brackets – for supporting rollers and maintaining stability.

-

Chains and belts – for consistent material flow.

-

Motorized pulleys – for driving conveyor belts efficiently.

-

Leveling pads and supports – to ensure alignment and reduce vibrations.

A single faulty conveyor part can halt production and cause significant financial losses. That’s why businesses depend on specialized manufacturers who provide durable, precisely engineered components tailored for specific applications.

By continuously innovating with advanced materials and designs, conveyor parts manufacturers contribute to faster, more efficient, and more sustainable industrial operations.

Why Industrial Components Manufacturers are Indispensable

The global industrial landscape is evolving rapidly with advancements in automation, robotics, and smart manufacturing. In this environment, industrial components manufacturers serve as the foundation for innovation. Their importance can be understood through the following points:

-

Customization and Flexibility

Every industry has unique needs. Manufacturers provide tailor-made solutions — whether it’s a customized control panel hinge or a conveyor roller designed for heavy-duty loads.

-

Quality and Reliability

High-quality components reduce downtime, extend machine life, and minimize maintenance costs. Industrial component suppliers adhere to strict quality standards to ensure performance and safety.

-

Global Supply Chain Support

From small factories to multinational corporations, industries worldwide rely on components manufactured with precision. Manufacturers ensure a steady supply of essential parts that keep the production cycle running.

-

Innovation and Sustainability

Many companies are investing in eco-friendly materials and energy-efficient designs. For instance, conveyor parts now incorporate lightweight yet durable materials to reduce energy consumption.

-

Cost-Effectiveness

By outsourcing specialized manufacturing, industries save on R&D and production costs while getting access to expertly crafted components.

Applications Across Key Industries

The contribution of industrial components spans multiple sectors:

-

Automotive: Fasteners, hinges, conveyor systems, and control panel parts streamline assembly lines.

-

Food Processing: Conveyor belts, rollers, and sanitary components ensure hygienic material handling.

-

Electronics: Precision locks, hinges, and cable management systems improve operational safety.

-

Construction: Heavy-duty components like panel locks and leveling pads maintain equipment stability.

-

Textiles: Conveyor systems enhance productivity and reduce manual handling.

Every sector depends on specialized manufacturers to deliver reliability and innovation.

Future Trends in Industrial Components Manufacturing

With technology reshaping industries, industrial components manufacturers are adapting rapidly. Some emerging trends include:

-

Smart Components

Sensors and IoT-enabled accessories are being integrated into control panels and conveyors for predictive maintenance.

-

Sustainable Manufacturing

Growing emphasis on recyclable materials and energy-efficient production processes.

-

Automation and Robotics

Advanced automation requires precision components with tighter tolerances and improved durability.

-

Globalization of Supply Chains

Manufacturers are expanding their reach to serve international markets with faster logistics.

-

Mass Customization

Businesses demand tailor-made solutions, leading manufacturers to adopt advanced technologies like 3D printing and CNC machining.

Choosing the Right Manufacturer

Selecting the right partner among industrial components manufacturers is critical. Businesses should evaluate:

-

Experience and expertise in producing components relevant to their industry.

-

Certifications and compliance with global standards like ISO and CE.

-

Capacity for customization to meet unique operational requirements.

-

After-sales support including warranties and maintenance services.

-

Commitment to sustainability and innovation.

A reliable manufacturer not only provides components but also acts as a partner in long-term growth and efficiency.

Conclusion

The role of industrial components manufacturers is far more significant than many realize. They are the hidden force behind the success of modern industries, supplying essential products like control panel accessories and working alongside conveyor parts manufacturers to ensure seamless operations.

As industries move toward smarter, greener, and more efficient systems, the demand for high-quality industrial components will only increase. By focusing on innovation, reliability, and customization, manufacturers continue to empower businesses to achieve operational excellence.

Whether it’s securing an electrical panel, optimizing a conveyor line, or ensuring machinery runs smoothly, the contribution of these manufacturers is indispensable. For industries aiming for growth and resilience in a competitive world, partnering with expert industrial component manufacturers is not just a choice — it’s a necessity.

Ball Plunger M.S.& S.S. SP-01

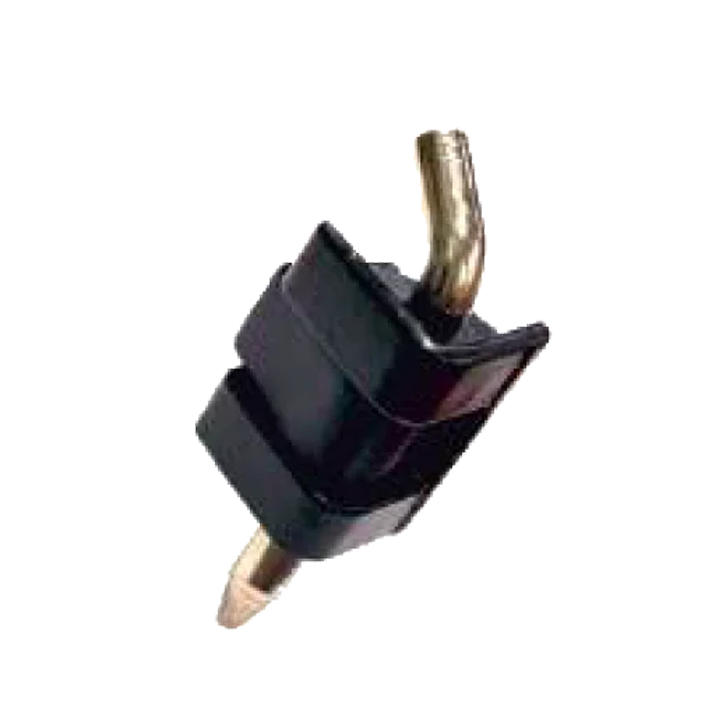

Ball Plunger M.S.& S.S. SP-01 Pin Plunger S.S. SP-02

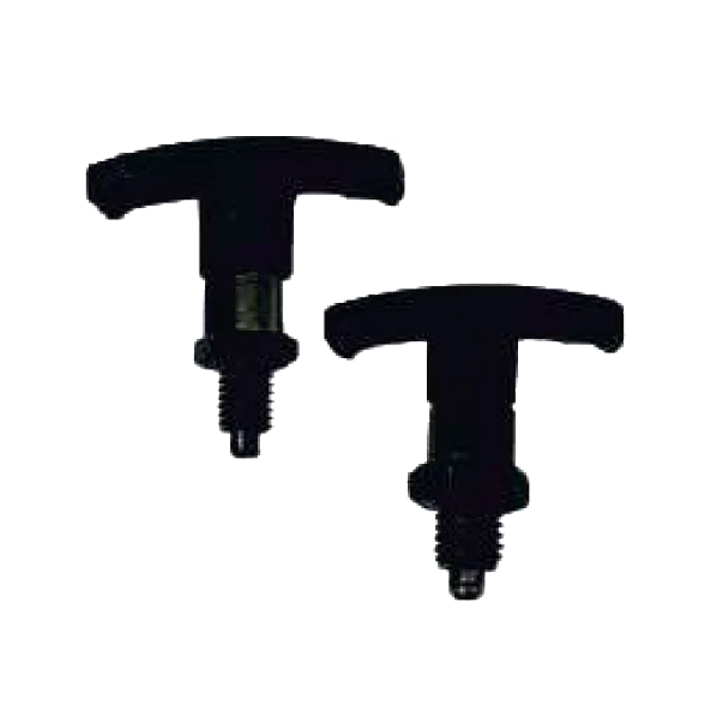

Pin Plunger S.S. SP-02 Index Plunger M.S& S.S. SP-03

Index Plunger M.S& S.S. SP-03 Index Plunger M.S& S.S. SP-05

Index Plunger M.S& S.S. SP-05 L Indexing Plunger SP-07

L Indexing Plunger SP-07 Screw Fit Plunger SP-08

Screw Fit Plunger SP-08 Press Fit Plunger SP-09

Press Fit Plunger SP-09 S.S. Press Fit Plunger SP.09-B

S.S. Press Fit Plunger SP.09-B Indexing Plunger SP-11

Indexing Plunger SP-11 Ball Spring Plungers SP-01

Ball Spring Plungers SP-01 Pin Plungers SP-02

Pin Plungers SP-02 Index Plungers SP-06

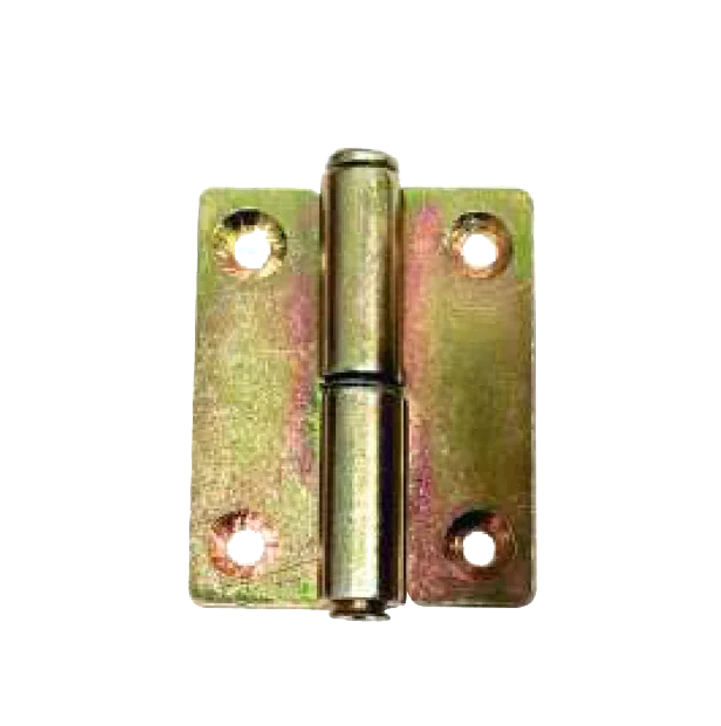

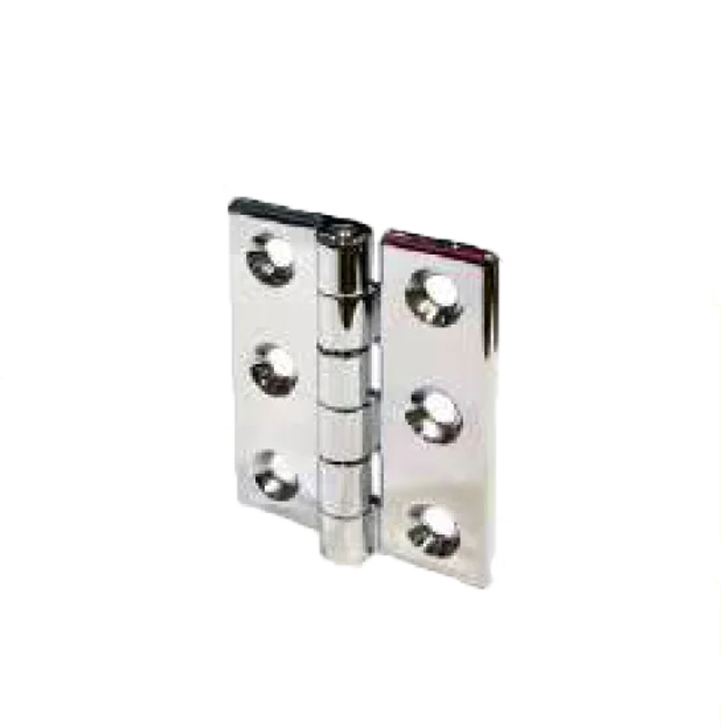

Index Plungers SP-06 M.S.& S.S. Hinges HS-42

M.S.& S.S. Hinges HS-42 M.S.& S.S Concealed HS-43

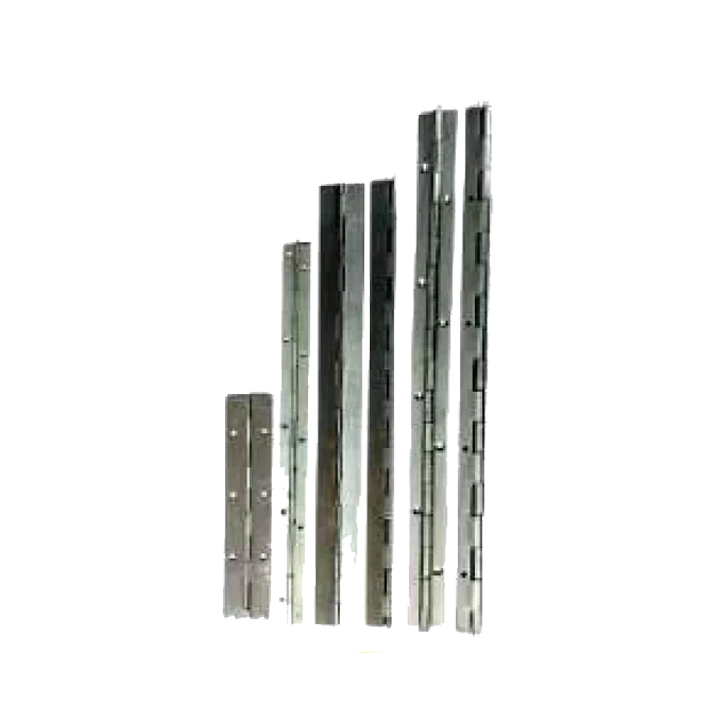

M.S.& S.S Concealed HS-43 S.S.304 Piano Hinges HS-44

S.S.304 Piano Hinges HS-44 Metal Hinges HS-45

Metal Hinges HS-45 M.S. Hinges HS-52

M.S. Hinges HS-52 S.S. 5036 HS-53

S.S. 5036 HS-53 S.S. Hinges HS-54 N

S.S. Hinges HS-54 N Poly 98*70 HS-57 N

Poly 98*70 HS-57 N Die-Cast 60*49 HS-68 N

Die-Cast 60*49 HS-68 N Die-Cast 50*40 HS-69 N

Die-Cast 50*40 HS-69 N Die-Cast 54*40 Bolted HS-70 N

Die-Cast 54*40 Bolted HS-70 N Damper Hinge 30mm HS-71 N

Damper Hinge 30mm HS-71 N Damper Hinge 50mm HS-72 N

Damper Hinge 50mm HS-72 N Bent Right Angle Hinge HS-73 N

Bent Right Angle Hinge HS-73 N DC Positioning Hinge HS-74 N

DC Positioning Hinge HS-74 N Brass 65*50 HS-75 N

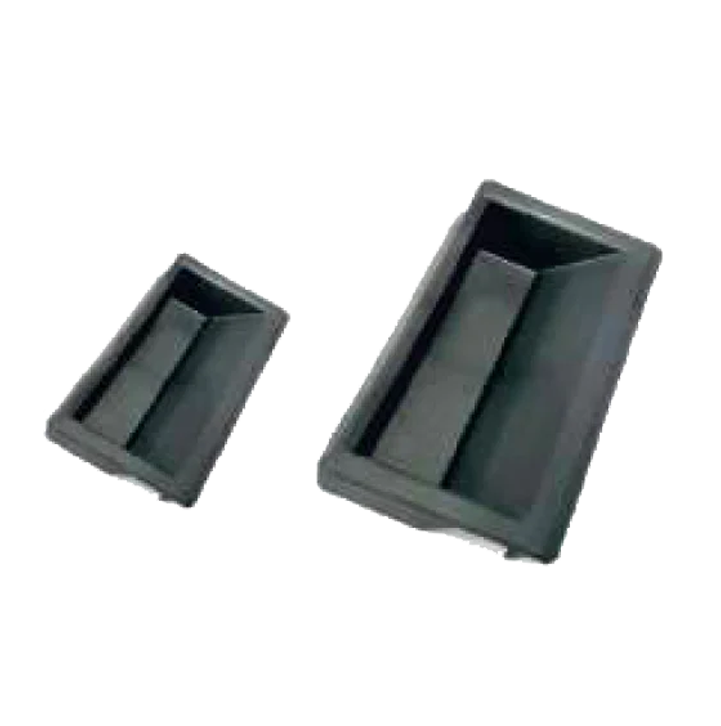

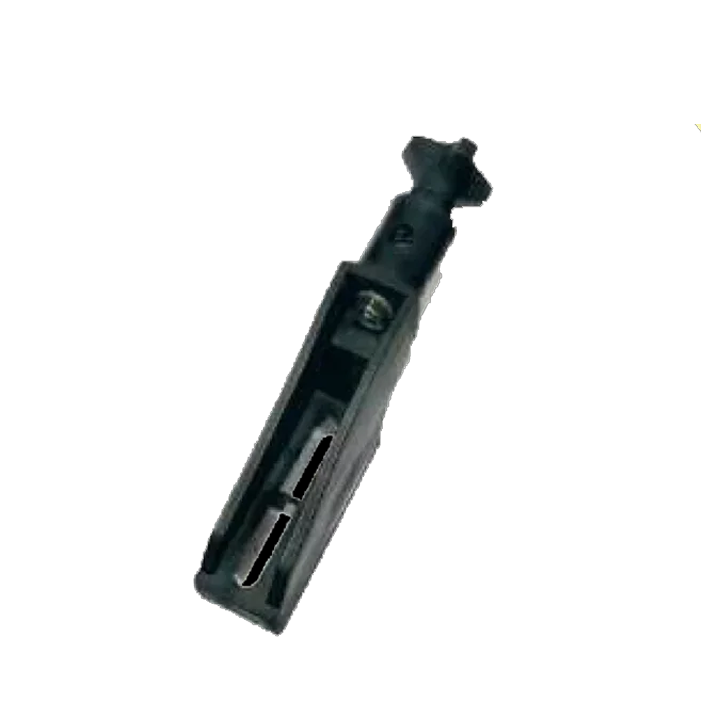

Brass 65*50 HS-75 N Poly 92 HL-01

Poly 92 HL-01 Poly 120 HL-02

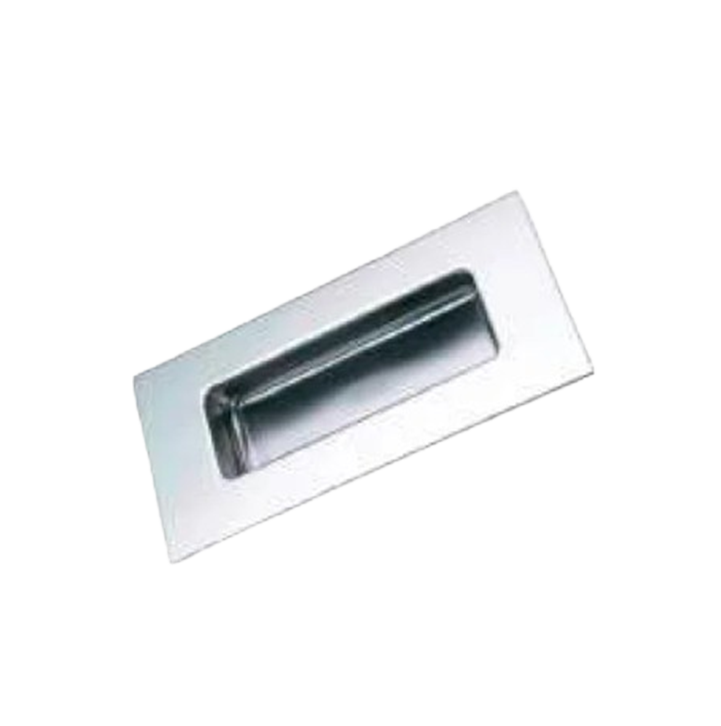

Poly 120 HL-02 Pocket Handle HL-05

Pocket Handle HL-05 Pocket Handle HL-05-B

Pocket Handle HL-05-B Die-Cast Adjustable HL-08

Die-Cast Adjustable HL-08 Polyamide Crank HL-11-A

Polyamide Crank HL-11-A Poly Revolving Handle HL-12-A

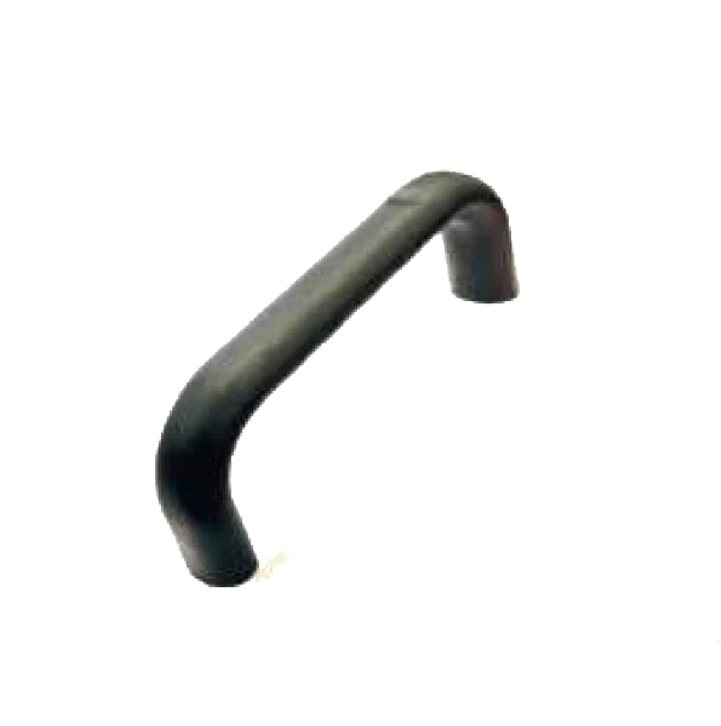

Poly Revolving Handle HL-12-A Curved Revolving Handle

Curved Revolving Handle M.S. Revolving Handle HL-12-C

M.S. Revolving Handle HL-12-C Metal Revolving Handle HL-12-E

Metal Revolving Handle HL-12-E Pipe Handle HL-13-B

Pipe Handle HL-13-B Pipe Handle HL-14

Pipe Handle HL-14 Poly HL-15

Poly HL-15 Poly HL-16

Poly HL-16 U-Handle Folding HL-17

U-Handle Folding HL-17 U-Handle Folding HL-19

U-Handle Folding HL-19 M.S. Handle HL-25

M.S. Handle HL-25 Poly Handle HL-20

Poly Handle HL-20 Strap Handle HL-21

Strap Handle HL-21 Pipe Handle HL-22

Pipe Handle HL-22 Pipe Handle HL-23

Pipe Handle HL-23 A.B.S. Handle HL-24

A.B.S. Handle HL-24 Poly HL-03

Poly HL-03 Polyamide Adjustable HL-09

Polyamide Adjustable HL-09 Polyamide Crank HL-11-B

Polyamide Crank HL-11-B Revolving Handle HL-12-D

Revolving Handle HL-12-D Pipe Handle HL-13-A

Pipe Handle HL-13-A Little Bracket 150mm CR-101

Little Bracket 150mm CR-101 Little Bracket 165mm CR-102

Little Bracket 165mm CR-102 Little Bracket 195mm CR-103

Little Bracket 195mm CR-103 Side Bracket 245mm CR-104

Side Bracket 245mm CR-104 Swivel Bracket 245mm CR-105

Swivel Bracket 245mm CR-105 Side Bracket 228mm CR-106

Side Bracket 228mm CR-106 Single Clamp CR-109

Single Clamp CR-109 Double Clamp 40mm CR-112

Double Clamp 40mm CR-112 Double Clamp 68mm CR-113

Double Clamp 68mm CR-113 Single Clamp M6 CR-114

Single Clamp M6 CR-114 Single Rod Guide CR-121

Single Rod Guide CR-121 Drip Tray Holder CR-122

Drip Tray Holder CR-122 Metal Leveling Pad MLP-05

Metal Leveling Pad MLP-05 Leveling Pad M.S.& S.S. LP-01

Leveling Pad M.S.& S.S. LP-01 Leveling Pad M.S.& S.S. LP-02

Leveling Pad M.S.& S.S. LP-02 Leveling Pad M.S.& S.S. LP-03

Leveling Pad M.S.& S.S. LP-03 Leveling Pad M.S.& S.S. LP-05

Leveling Pad M.S.& S.S. LP-05 M.S.& S.S. Leveling Pad MLP-01

M.S.& S.S. Leveling Pad MLP-01 M.S.& S.S. Leveling Pad MLP-02

M.S.& S.S. Leveling Pad MLP-02 M.S. Leveling Pad MLP-03

M.S. Leveling Pad MLP-03 S.S.304 Leveling Pad MLP-04

S.S.304 Leveling Pad MLP-04 Foot Mount M.S. FM-01

Foot Mount M.S. FM-01 Foot Mount M.S. FM-02

Foot Mount M.S. FM-02 Foot Mount M.S.& S.S. FM-03

Foot Mount M.S.& S.S. FM-03 Clamp 90mm M S S S CL-01-A

Clamp 90mm M S S S CL-01-A Clamp 102mm M S S S CL-01-B

Clamp 102mm M S S S CL-01-B Clamp 54mm M S S S CL-02-A

Clamp 54mm M S S S CL-02-A Clamp 54mm M S S S CL-02-B

Clamp 54mm M S S S CL-02-B Clamp 100mm M S S S CL-03

Clamp 100mm M S S S CL-03 Clamp 100mm M S S S CL-04

Clamp 100mm M S S S CL-04 Clamp 125mm M S CL-05

Clamp 125mm M S CL-05 Clamp M S S S CL-06

Clamp M S S S CL-06 Clamp M S S S CL-07

Clamp M S S S CL-07 Spring Clamp M S S S CL-08-A

Spring Clamp M S S S CL-08-A Spring Clamp M S S S CL-08-B

Spring Clamp M S S S CL-08-B Clamp 110mm M S S S CL-09

Clamp 110mm M S S S CL-09 Spring Clamp M S S S CL-11

Spring Clamp M S S S CL-11 Spring Clamp M S S S CL-12-A

Spring Clamp M S S S CL-12-A Spring Clamp M S S S CL-12-B

Spring Clamp M S S S CL-12-B Small Clamp M S S S CL-13

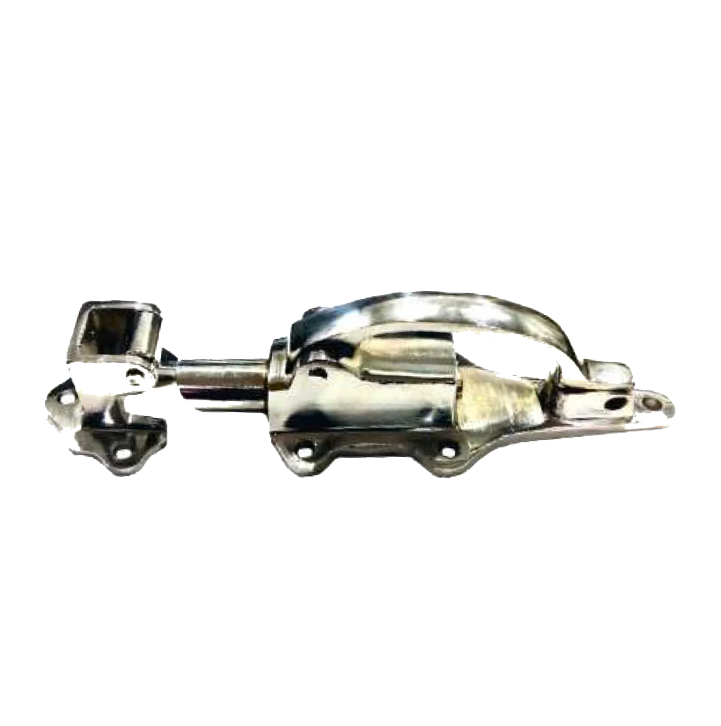

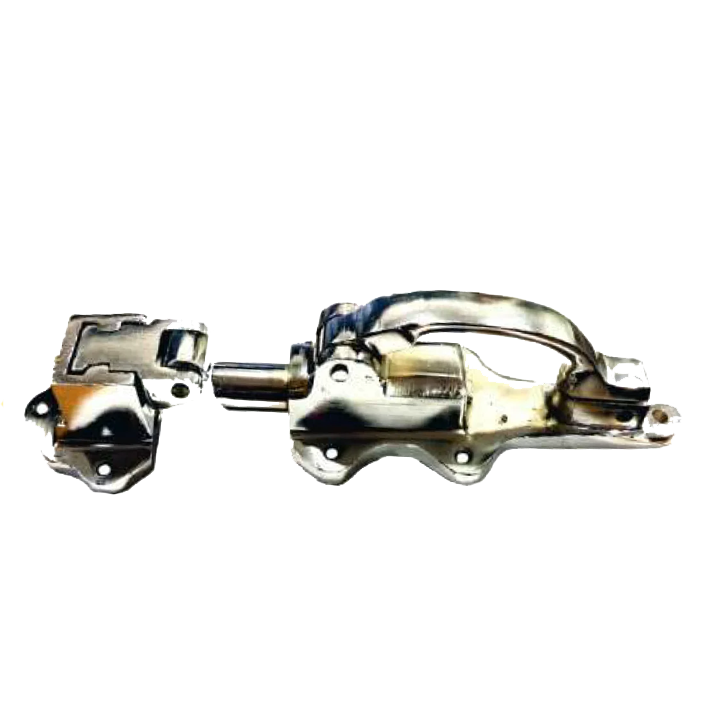

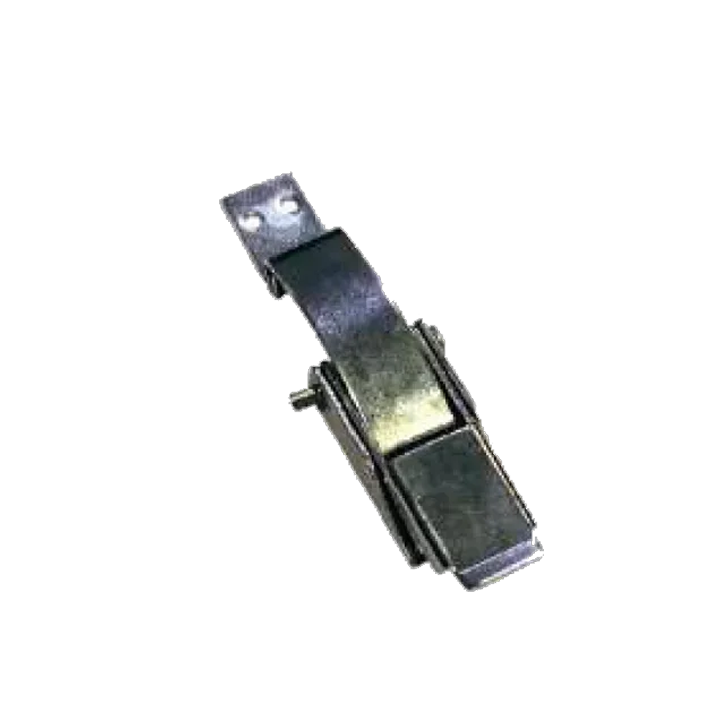

Small Clamp M S S S CL-13 Die-Cast Lift Off HS-01

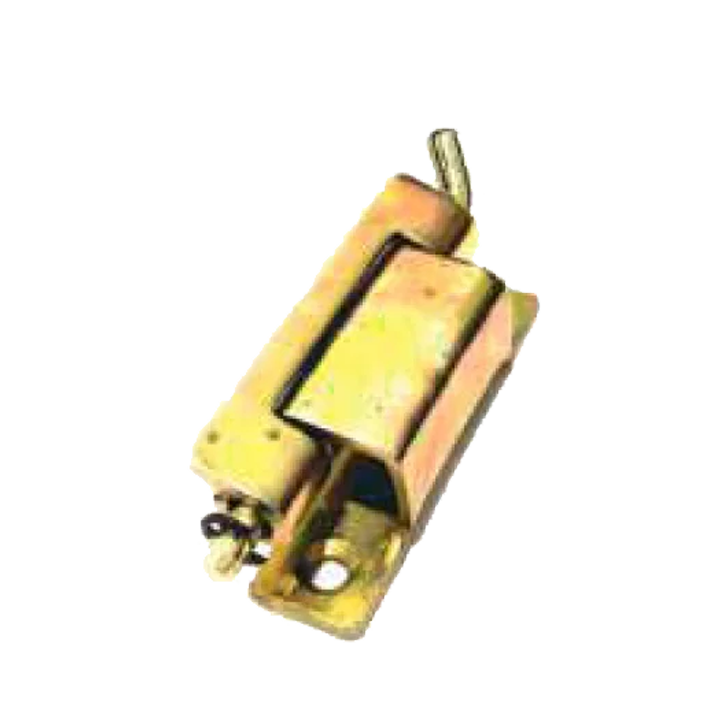

Die-Cast Lift Off HS-01 M S Siemens HS-02-A

M S Siemens HS-02-A M S Siemens HS-02-B

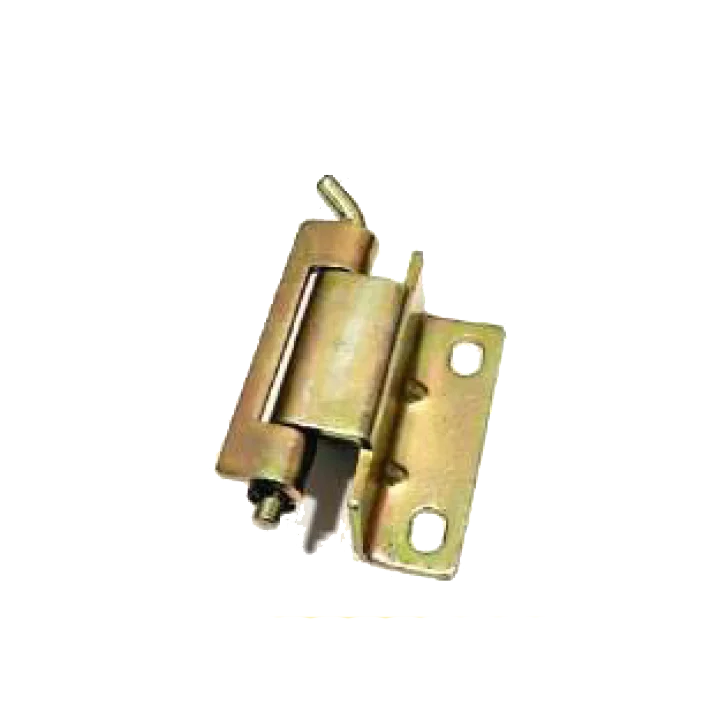

M S Siemens HS-02-B M S Siemens HS-02-C

M S Siemens HS-02-C M S Siemens HS-03

M S Siemens HS-03 M S Lift Off HS-04

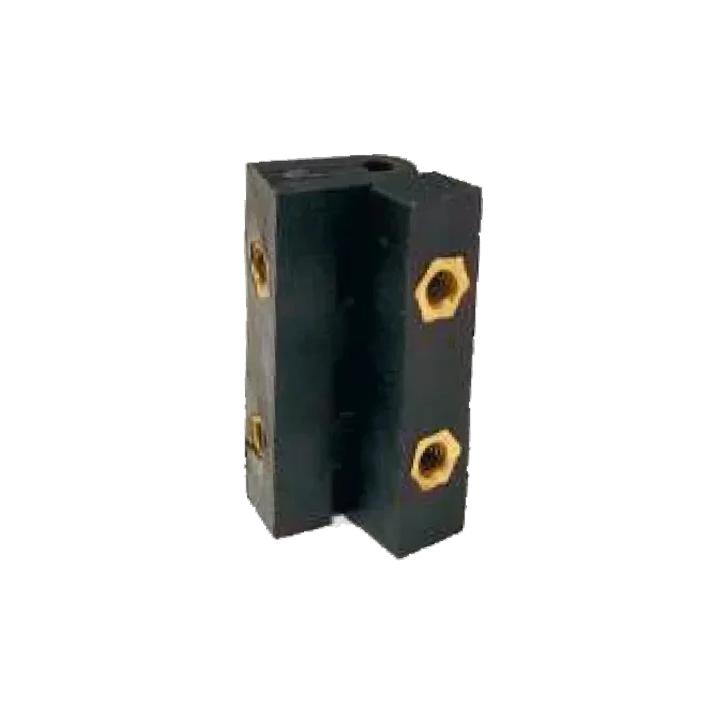

M S Lift Off HS-04 M S Consealed HS-06-A

M S Consealed HS-06-A M S Consealed HS-06-B

M S Consealed HS-06-B M S S S Consealed HS-07

M S S S Consealed HS-07 Spring Type S S M S HS-08

Spring Type S S M S HS-08 Spring Type HS-09

Spring Type HS-09 L T M S S S HS-10

L T M S S S HS-10 S S Spring HS-11

S S Spring HS-11 Capsule-Type S S M S HS-12

Capsule-Type S S M S HS-12 L T M S S S HS-13

L T M S S S HS-13 Z-TYPE HS-13-Z

Z-TYPE HS-13-Z Poly Profile HS-25

Poly Profile HS-25 Poly 7048/4530 HS-26

Poly 7048/4530 HS-26 Poly 4048/ 2630 HS-50

Poly 4048/ 2630 HS-50 Poly 3048/ 1230 HS-51

Poly 3048/ 1230 HS-51 Poly 5070 HS-27

Poly 5070 HS-27 Poly 4849 HS-28

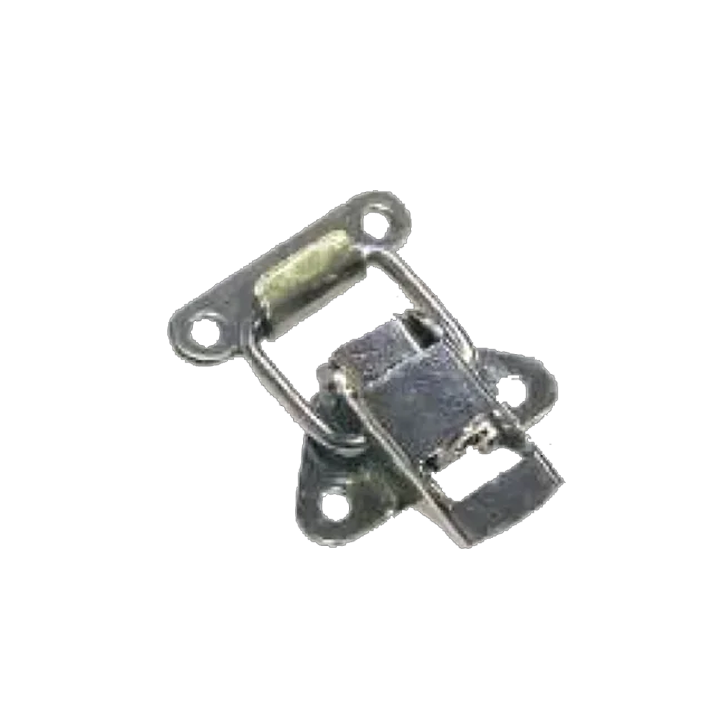

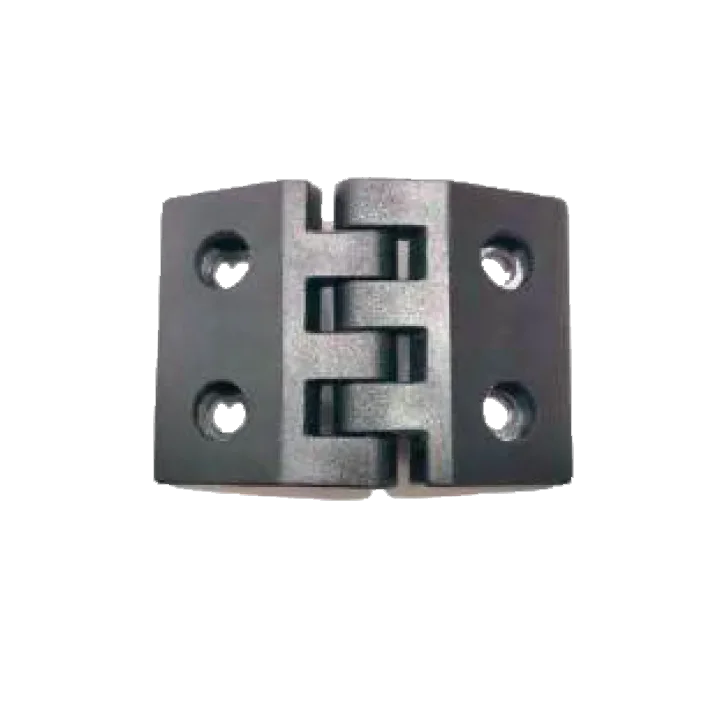

Poly 4849 HS-28 Die-Cast S.S. 4 Hole HS-30

Die-Cast S.S. 4 Hole HS-30 Die-Cast 50*63

Die-Cast 50*63 Die-Cast 50*76

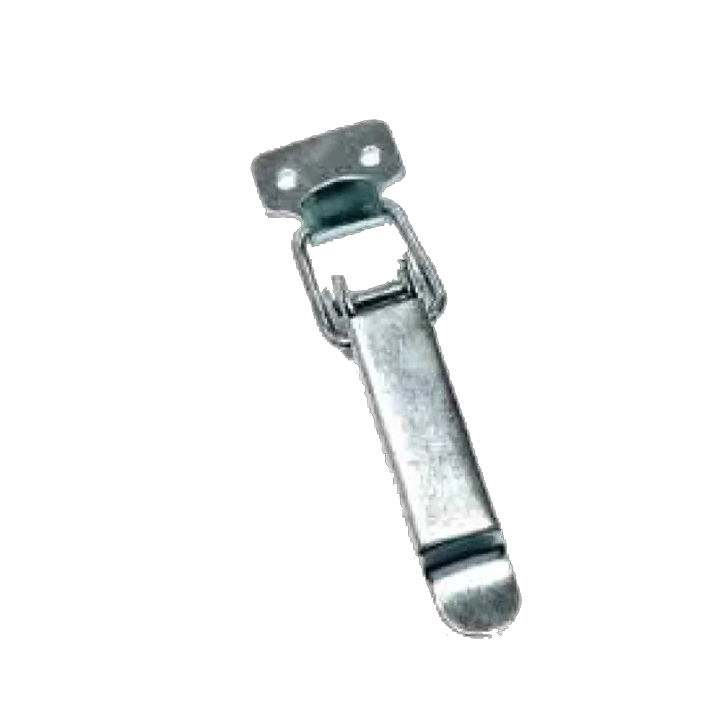

Die-Cast 50*76 Die-Cast Bolted HS-31-A

Die-Cast Bolted HS-31-A Die-Cast HS-21-B

Die-Cast HS-21-B Die-Cast Rittal HS-32-A

Die-Cast Rittal HS-32-A Mild Steel Rittal HS-32-B

Mild Steel Rittal HS-32-B Polyamide 046 HS-33

Polyamide 046 HS-33 Poly 4 Hole

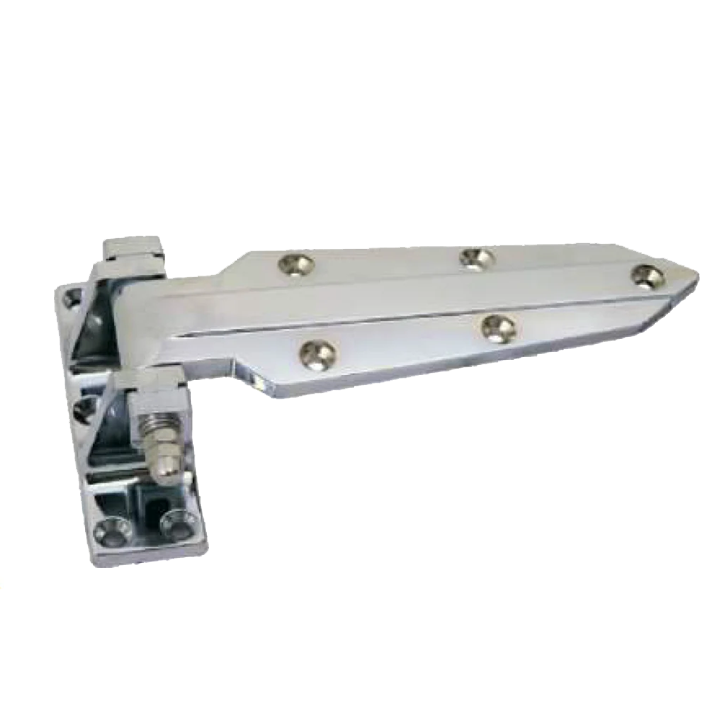

Poly 4 Hole M.S.& S.S. Hinges HS-38

M.S.& S.S. Hinges HS-38 Die Cast Hinges HS-62

Die Cast Hinges HS-62 M.S. Hinges HS-37

M.S. Hinges HS-37 MS & S.S. Hinges HS-35

MS & S.S. Hinges HS-35 S.S. Lift Off Hinges

S.S. Lift Off Hinges S.S. Butt Hinges HS-40-B

S.S. Butt Hinges HS-40-B M.S.& S.S. Hinges HS-41

M.S.& S.S. Hinges HS-41 Conveyor Guide

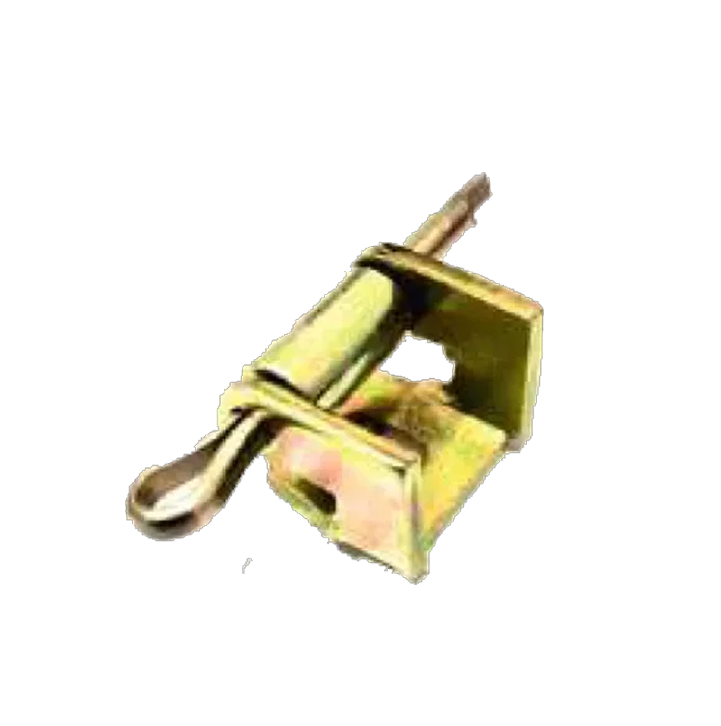

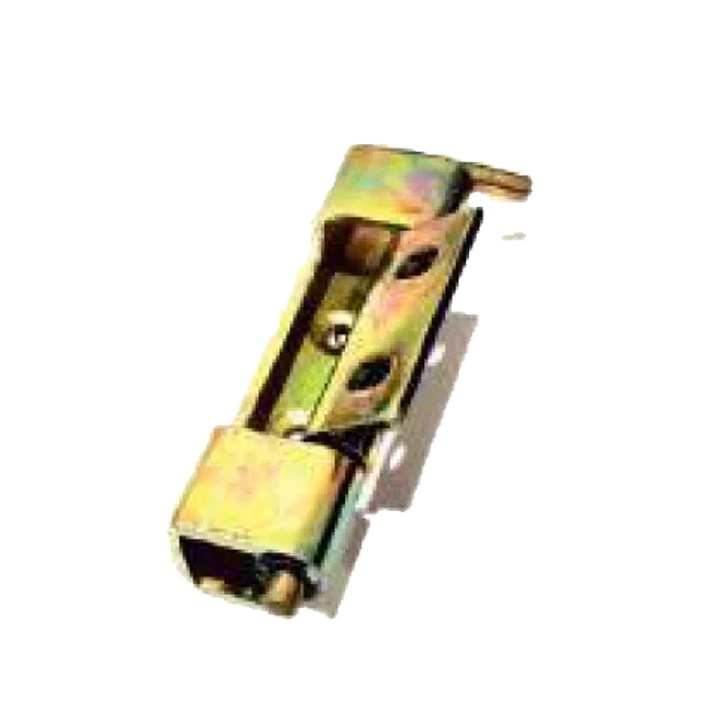

Conveyor Guide Conveyor Clamps

Conveyor Clamps Support Base CR-201

Support Base CR-201 Support Base CR-202

Support Base CR-202 Support Base CR-203

Support Base CR-203 Drip Tray Supports CR.252

Drip Tray Supports CR.252 Fixing Washer CR.338

Fixing Washer CR.338 Clamp For Sensor CR.341

Clamp For Sensor CR.341 Connecting Joints CR.501

Connecting Joints CR.501 Support Head CR-502-A

Support Head CR-502-A Support Head CR-502-B

Support Head CR-502-B Side Mounting Bracket CR.513

Side Mounting Bracket CR.513 Round Tube Ends CR.708

Round Tube Ends CR.708 Square Tube Ends CR.710

Square Tube Ends CR.710