Essential Conveyor Parts Accessories Every Manufacturer Should Consider

Author / Date: 30 Aug, 2025

The modern manufacturing industry would not be possible without conveyor systems, which greatly facilitate the flow of materials and contributes to high productivity in any industry. The quality and compatibility of the accessories of these systems however, determines their efficiency as well as their longevity. Channel industries being a market leader in the production of conveyor parts and accessories, has a complete line of products that helps to maximize performance in operations. Conveyor side bracket to level pad, knowing these elements will go a long way to save you time, offer safety, and overall efficiency of your material handling systems.

Why Conveyor Accessories Matter

Many manufacturers focus primarily on the conveyor belt and motor, often overlooking the essential accessories that ensure smooth operation. Accessories play a crucial role in:

-

Supporting Structural Integrity: Components like support bases and side brackets keep the conveyor stable and aligned.

-

Reducing Maintenance Needs: High-quality accessories reduce wear and tear, preventing frequent breakdowns.

-

Enhancing Safety: Items like handwheels and plungers allow for safe adjustments and emergency interventions.

-

Increasing Efficiency: Properly selected leveling pads and castor wheels can improve workflow and system mobility.

Investing in the right accessories from Channel Industries ensures your conveyor systems perform at peak efficiency while minimizing operational risks.

Key Conveyor Accessories

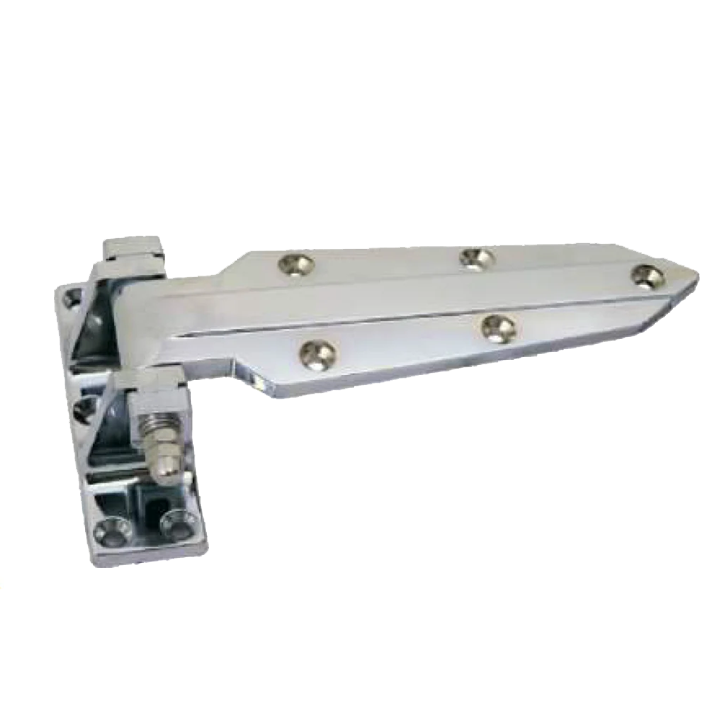

1. Conveyor Side Brackets

Conveyor side brackets are essential for supporting the frame and ensuring structural stability. They prevent lateral movement and help maintain proper alignment, which is critical for materials to move smoothly along the belt. Channel Industries offers robust side brackets designed to withstand heavy loads and harsh industrial environments.

2. Leveling Pads

Leveling pads are installed under the conveyor to adjust height and maintain a perfectly level surface. Uneven floors can cause belt misalignment, increased wear, and operational inefficiency. With Channel Industries’ high-quality leveling pads, manufacturers can achieve precise adjustments, enhancing conveyor performance and reducing downtime.

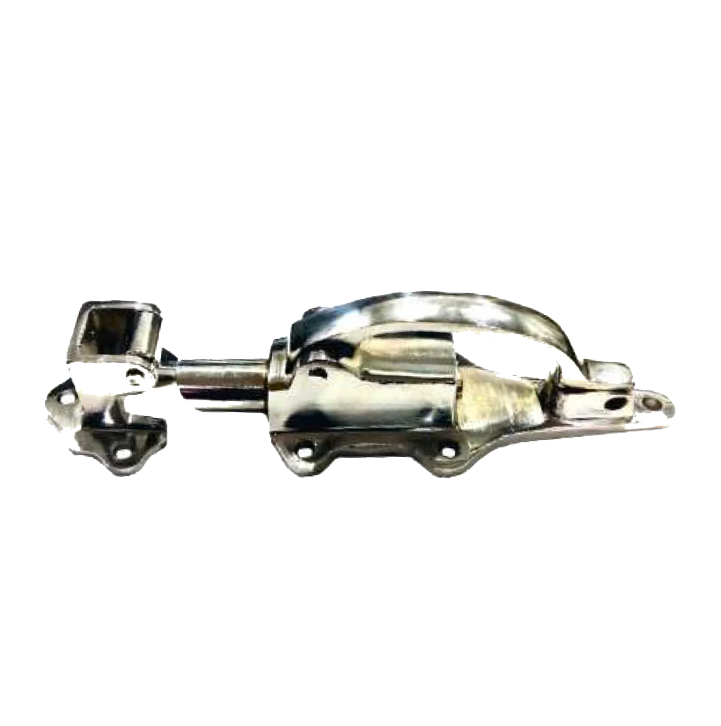

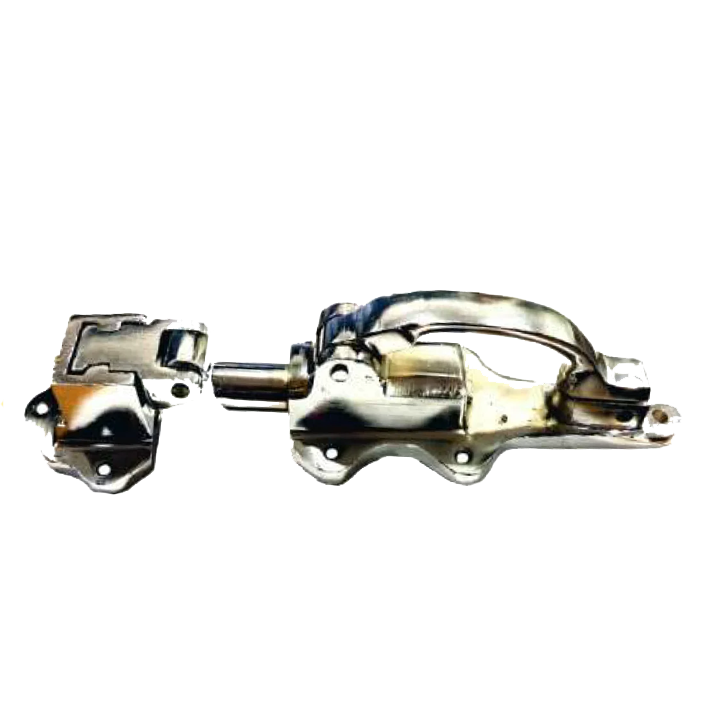

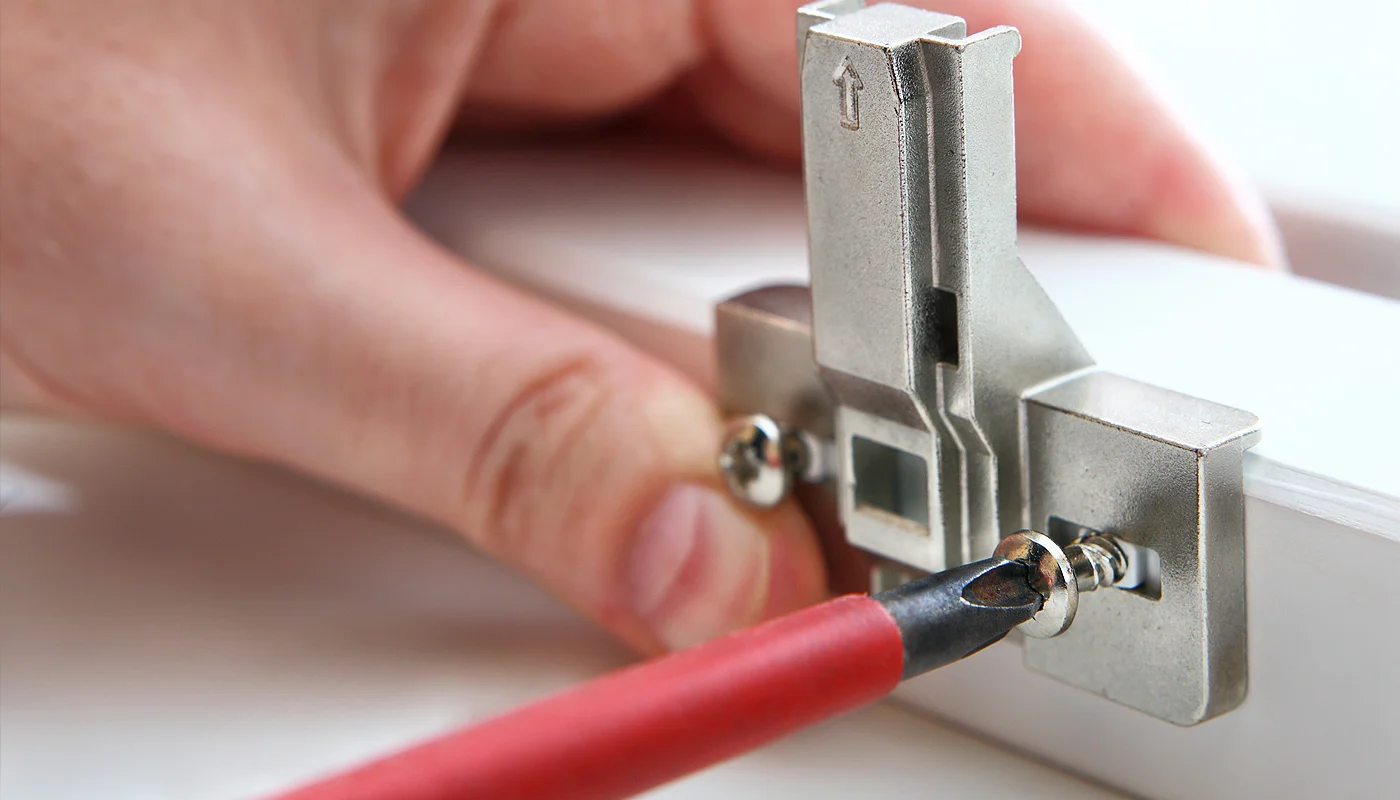

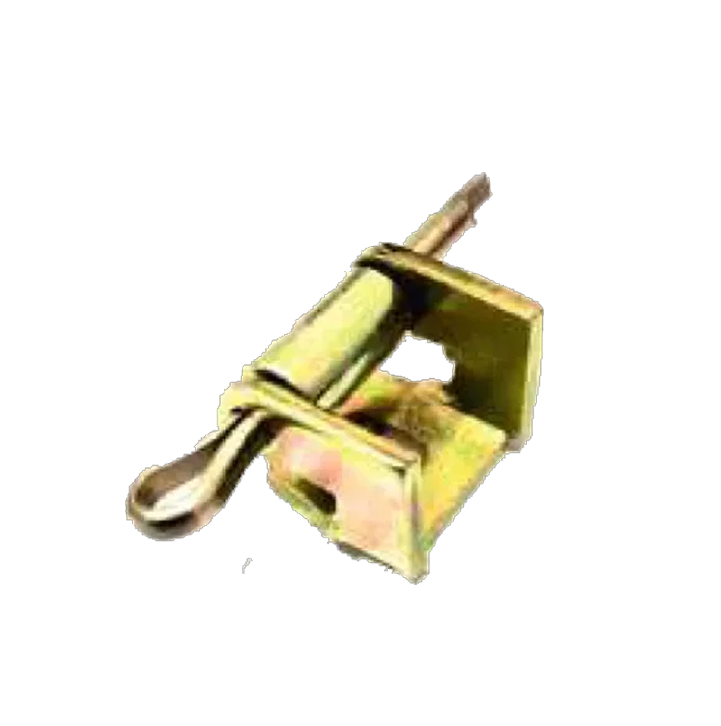

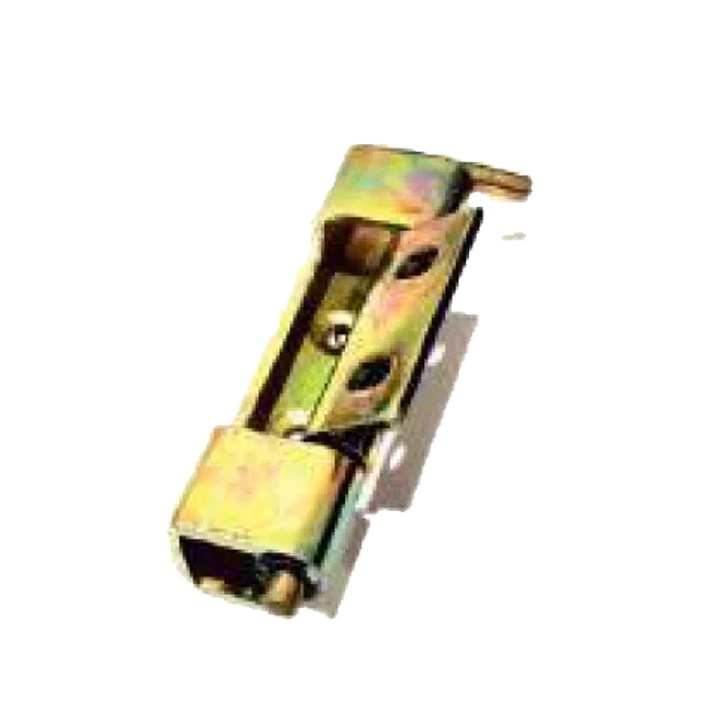

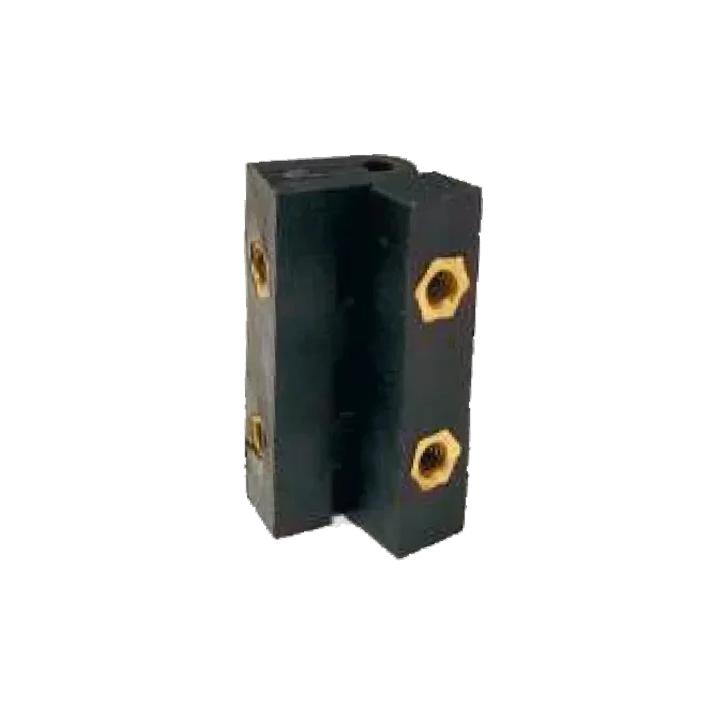

3. Heavy Duty Panel Locks

Safety is a top priority in any manufacturing setting. Heavy-duty panel locks secure access panels on conveyor systems, preventing unauthorized or accidental openings. This not only ensures worker safety but also protects internal components from dust, debris, and damage.

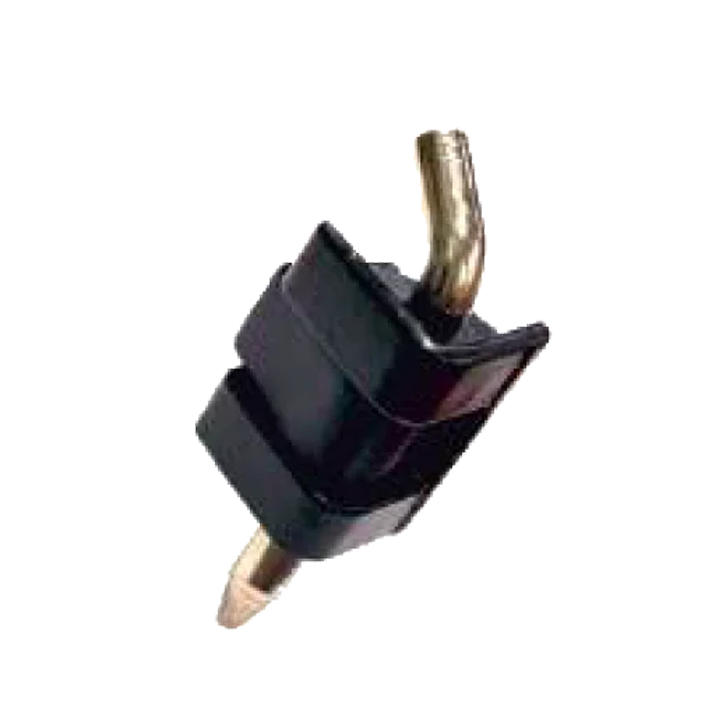

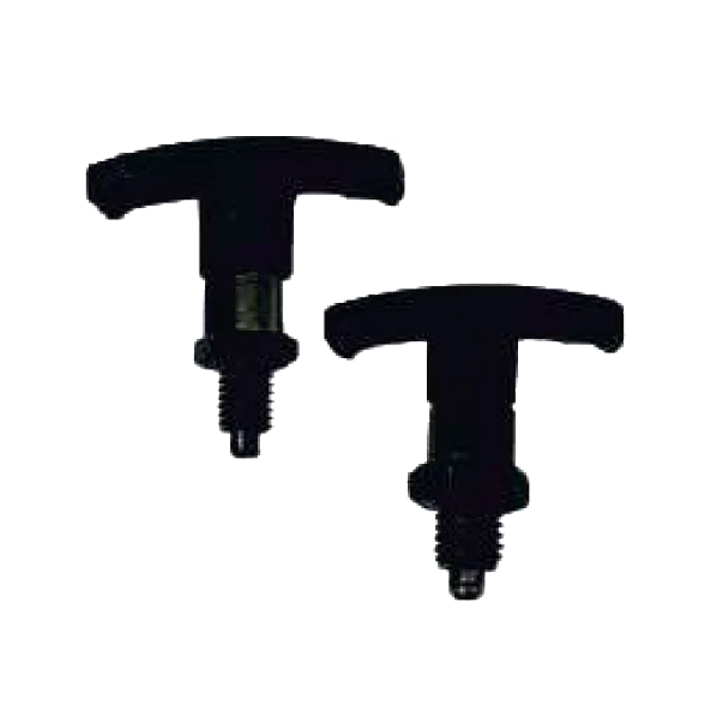

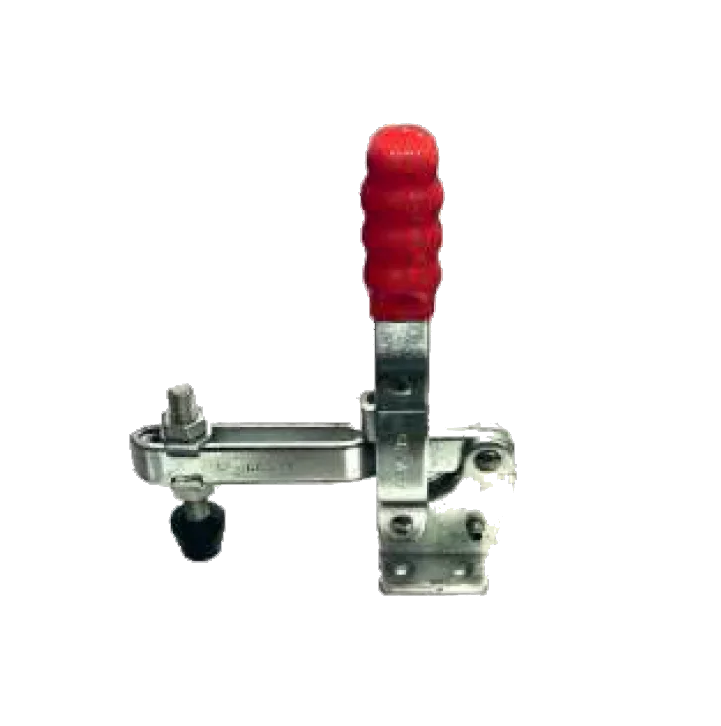

4. Handwheels and Plungers

Handwheels and plungers are simple yet crucial accessories for conveyor adjustment. They allow operators to make quick, precise changes to the conveyor setup, whether it’s belt tension, alignment, or component positioning. Ergonomically designed handwheels reduce strain, while plungers provide secure locking mechanisms for movable parts.

5. Castor Wheels

Mobility is vital for flexible manufacturing lines. Castor wheels enable easy relocation of conveyors for maintenance, reconfiguration, or space optimization. Channel Industries’ castor wheels are durable, designed to handle heavy loads, and equipped with smooth-rolling mechanisms for effortless movement.

6. Support Bases

Support bases, including tripod-style bases, provide foundational support for conveyor systems. They absorb vibrations, distribute load evenly, and ensure long-term stability. Using quality support bases reduces the stress on the conveyor frame and components, extending the lifespan of the system.

Benefits of Choosing High-Quality Accessories

-

Extended Equipment Lifespan: Durable accessories reduce wear and tear on main conveyor components.

-

Reduced Downtime: Reliable parts minimize breakdowns and maintenance requirements.

-

Enhanced Operational Safety: Properly designed accessories prevent accidents and protect workers.

-

Improved Productivity: Smooth operation ensures materials move efficiently through production lines.

-

Cost Efficiency: While quality accessories may have a higher upfront cost, they reduce repair costs and improve ROI in the long run.

How to Select the Right Conveyor Accessories

Choosing the right accessories requires careful consideration of several factors:

-

Load Capacity: Ensure components can handle the weight of the materials transported.

-

Environment: Consider temperature, dust, moisture, and chemical exposure in your facility.

-

Compatibility: Accessories must be compatible with existing conveyor systems.

-

Ease of Maintenance: Opt for parts that are easy to install, adjust, and replace.

-

Manufacturer Reputation: Reliable suppliers like Channel Industries offer tested and durable products with warranties and after-sales support.

Applications Across Industries

Conveyor systems and their accessories are used across various sectors, including:

-

Food Processing: Transporting raw materials, packaging, and finished goods.

-

Automotive Manufacturing: Moving parts along assembly lines efficiently.

-

Warehousing and Logistics: Handling packages and inventory with speed and precision.

-

Pharmaceuticals: Ensuring safe and hygienic transportation of products.

-

Mining and Heavy Industry: Moving raw materials, ores, and finished components safely.

Why Choose Channel Industries

Channel Industries has established itself as a trusted Conveyor Parts Manufacturer in India. Their products are known for durability, precision, and reliability. By offering a wide range of accessories including flat hinges, plungers, leveling pads, castor wheels, and heavy-duty panel locks, they cater to diverse industrial needs. Partnering with Channel Industries ensures access to high-quality parts that keep your operations running smoothly, efficiently, and safely.

Conclusion

Conveyor accessories may seem like small components, but their impact on operational efficiency and safety is significant. From side brackets and leveling pads to handwheels, plungers, and castor wheels, choosing high-quality accessories from Channel Industries ensures your conveyor systems perform at their best. Proper investment in these components reduces downtime, enhances productivity, and extends the life of your equipment. For manufacturers looking for reliability and performance, Channel Industries is the go-to partner for all conveyor accessory needs.

Ball Plunger M.S.& S.S. SP-01

Ball Plunger M.S.& S.S. SP-01 Pin Plunger S.S. SP-02

Pin Plunger S.S. SP-02 Index Plunger M.S& S.S. SP-03

Index Plunger M.S& S.S. SP-03 Index Plunger M.S& S.S. SP-05

Index Plunger M.S& S.S. SP-05 L Indexing Plunger SP-07

L Indexing Plunger SP-07 Screw Fit Plunger SP-08

Screw Fit Plunger SP-08 Press Fit Plunger SP-09

Press Fit Plunger SP-09 S.S. Press Fit Plunger SP.09-B

S.S. Press Fit Plunger SP.09-B Indexing Plunger SP-11

Indexing Plunger SP-11 Ball Spring Plungers SP-01

Ball Spring Plungers SP-01 Pin Plungers SP-02

Pin Plungers SP-02 Index Plungers SP-06

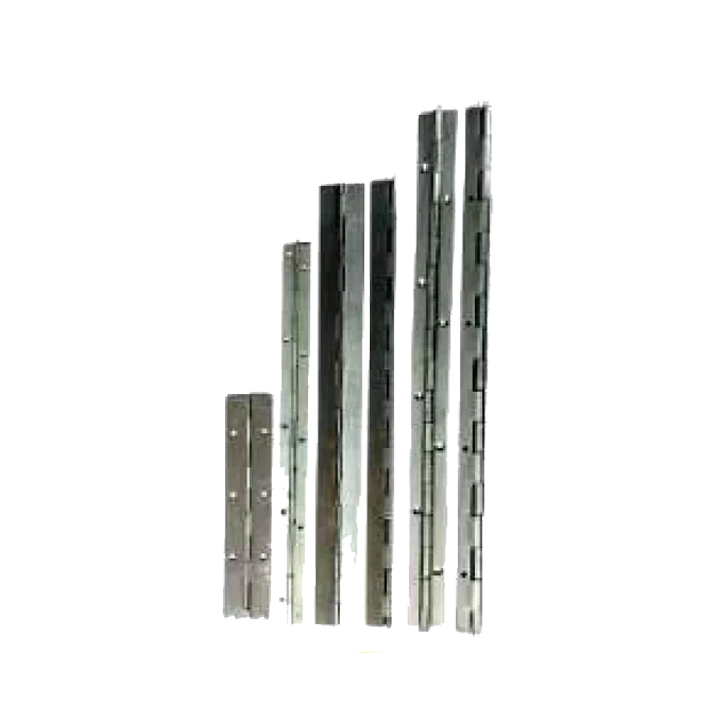

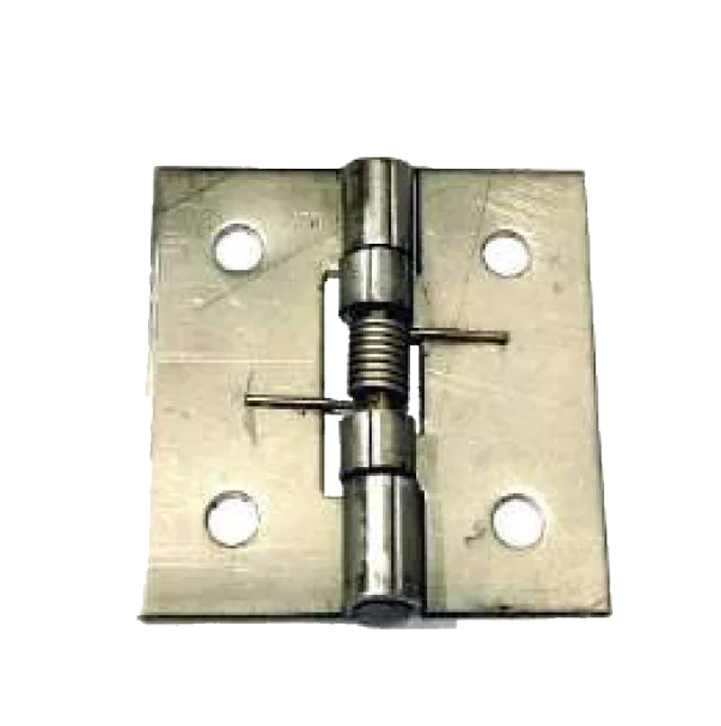

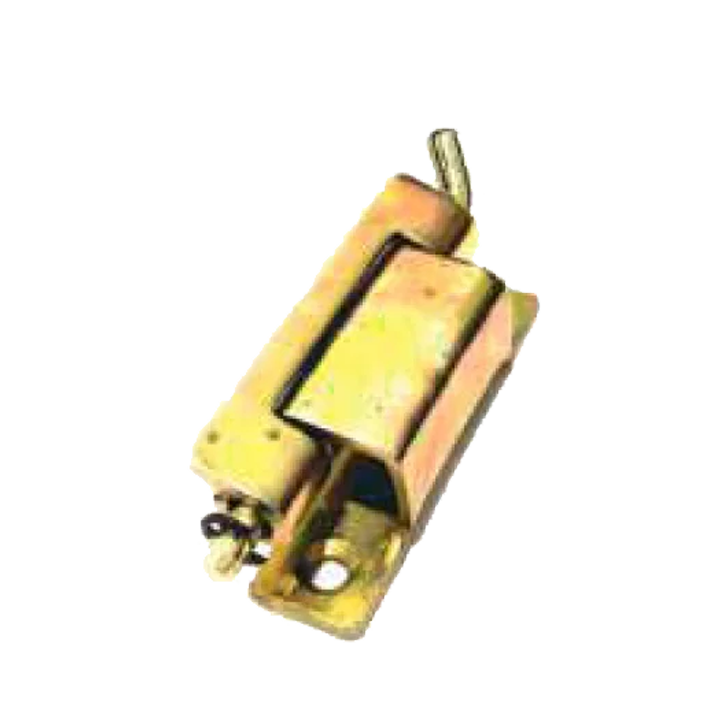

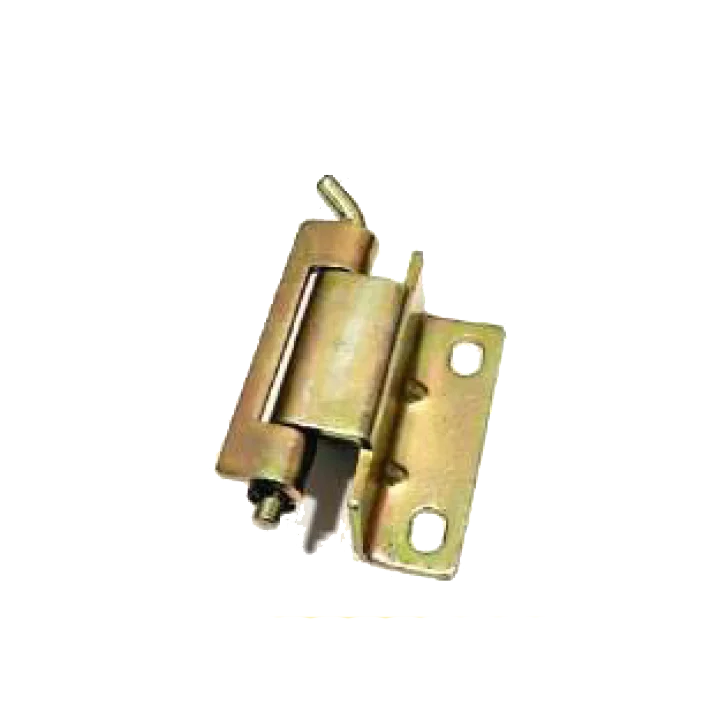

Index Plungers SP-06 M.S.& S.S. Hinges HS-42

M.S.& S.S. Hinges HS-42 M.S.& S.S Concealed HS-43

M.S.& S.S Concealed HS-43 S.S.304 Piano Hinges HS-44

S.S.304 Piano Hinges HS-44 Metal Hinges HS-45

Metal Hinges HS-45 M.S. Hinges HS-52

M.S. Hinges HS-52 S.S. 5036 HS-53

S.S. 5036 HS-53 S.S. Hinges HS-54 N

S.S. Hinges HS-54 N Poly 98*70 HS-57 N

Poly 98*70 HS-57 N Die-Cast 60*49 HS-68 N

Die-Cast 60*49 HS-68 N Die-Cast 50*40 HS-69 N

Die-Cast 50*40 HS-69 N Die-Cast 54*40 Bolted HS-70 N

Die-Cast 54*40 Bolted HS-70 N Damper Hinge 30mm HS-71 N

Damper Hinge 30mm HS-71 N Damper Hinge 50mm HS-72 N

Damper Hinge 50mm HS-72 N Bent Right Angle Hinge HS-73 N

Bent Right Angle Hinge HS-73 N DC Positioning Hinge HS-74 N

DC Positioning Hinge HS-74 N Brass 65*50 HS-75 N

Brass 65*50 HS-75 N Poly 92 HL-01

Poly 92 HL-01 Poly 120 HL-02

Poly 120 HL-02 Pocket Handle HL-05

Pocket Handle HL-05 Pocket Handle HL-05-B

Pocket Handle HL-05-B Die-Cast Adjustable HL-08

Die-Cast Adjustable HL-08 Polyamide Crank HL-11-A

Polyamide Crank HL-11-A Poly Revolving Handle HL-12-A

Poly Revolving Handle HL-12-A Curved Revolving Handle

Curved Revolving Handle M.S. Revolving Handle HL-12-C

M.S. Revolving Handle HL-12-C Metal Revolving Handle HL-12-E

Metal Revolving Handle HL-12-E Pipe Handle HL-13-B

Pipe Handle HL-13-B Pipe Handle HL-14

Pipe Handle HL-14 Poly HL-15

Poly HL-15 Poly HL-16

Poly HL-16 U-Handle Folding HL-17

U-Handle Folding HL-17 U-Handle Folding HL-19

U-Handle Folding HL-19 M.S. Handle HL-25

M.S. Handle HL-25 Poly Handle HL-20

Poly Handle HL-20 Strap Handle HL-21

Strap Handle HL-21 Pipe Handle HL-22

Pipe Handle HL-22 Pipe Handle HL-23

Pipe Handle HL-23 A.B.S. Handle HL-24

A.B.S. Handle HL-24 Poly HL-03

Poly HL-03 Polyamide Adjustable HL-09

Polyamide Adjustable HL-09 Polyamide Crank HL-11-B

Polyamide Crank HL-11-B Revolving Handle HL-12-D

Revolving Handle HL-12-D Pipe Handle HL-13-A

Pipe Handle HL-13-A Little Bracket 150mm CR-101

Little Bracket 150mm CR-101 Little Bracket 165mm CR-102

Little Bracket 165mm CR-102 Little Bracket 195mm CR-103

Little Bracket 195mm CR-103 Side Bracket 245mm CR-104

Side Bracket 245mm CR-104 Swivel Bracket 245mm CR-105

Swivel Bracket 245mm CR-105 Side Bracket 228mm CR-106

Side Bracket 228mm CR-106 Single Clamp CR-109

Single Clamp CR-109 Double Clamp 40mm CR-112

Double Clamp 40mm CR-112 Double Clamp 68mm CR-113

Double Clamp 68mm CR-113 Single Clamp M6 CR-114

Single Clamp M6 CR-114 Single Rod Guide CR-121

Single Rod Guide CR-121 Drip Tray Holder CR-122

Drip Tray Holder CR-122 Metal Leveling Pad MLP-05

Metal Leveling Pad MLP-05 Leveling Pad M.S.& S.S. LP-01

Leveling Pad M.S.& S.S. LP-01 Leveling Pad M.S.& S.S. LP-02

Leveling Pad M.S.& S.S. LP-02 Leveling Pad M.S.& S.S. LP-03

Leveling Pad M.S.& S.S. LP-03 Leveling Pad M.S.& S.S. LP-05

Leveling Pad M.S.& S.S. LP-05 M.S.& S.S. Leveling Pad MLP-01

M.S.& S.S. Leveling Pad MLP-01 M.S.& S.S. Leveling Pad MLP-02

M.S.& S.S. Leveling Pad MLP-02 M.S. Leveling Pad MLP-03

M.S. Leveling Pad MLP-03 S.S.304 Leveling Pad MLP-04

S.S.304 Leveling Pad MLP-04 Foot Mount M.S. FM-01

Foot Mount M.S. FM-01 Foot Mount M.S. FM-02

Foot Mount M.S. FM-02 Foot Mount M.S.& S.S. FM-03

Foot Mount M.S.& S.S. FM-03 Clamp 90mm M S S S CL-01-A

Clamp 90mm M S S S CL-01-A Clamp 102mm M S S S CL-01-B

Clamp 102mm M S S S CL-01-B Clamp 54mm M S S S CL-02-A

Clamp 54mm M S S S CL-02-A Clamp 54mm M S S S CL-02-B

Clamp 54mm M S S S CL-02-B Clamp 100mm M S S S CL-03

Clamp 100mm M S S S CL-03 Clamp 100mm M S S S CL-04

Clamp 100mm M S S S CL-04 Clamp 125mm M S CL-05

Clamp 125mm M S CL-05 Clamp M S S S CL-06

Clamp M S S S CL-06 Clamp M S S S CL-07

Clamp M S S S CL-07 Spring Clamp M S S S CL-08-A

Spring Clamp M S S S CL-08-A Spring Clamp M S S S CL-08-B

Spring Clamp M S S S CL-08-B Clamp 110mm M S S S CL-09

Clamp 110mm M S S S CL-09 Spring Clamp M S S S CL-11

Spring Clamp M S S S CL-11 Spring Clamp M S S S CL-12-A

Spring Clamp M S S S CL-12-A Spring Clamp M S S S CL-12-B

Spring Clamp M S S S CL-12-B Small Clamp M S S S CL-13

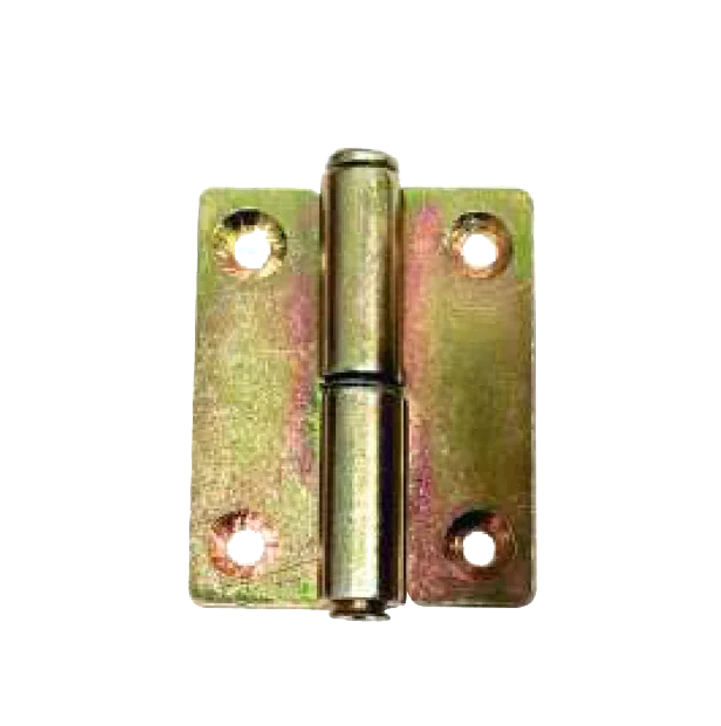

Small Clamp M S S S CL-13 Die-Cast Lift Off HS-01

Die-Cast Lift Off HS-01 M S Siemens HS-02-A

M S Siemens HS-02-A M S Siemens HS-02-B

M S Siemens HS-02-B M S Siemens HS-02-C

M S Siemens HS-02-C M S Siemens HS-03

M S Siemens HS-03 M S Lift Off HS-04

M S Lift Off HS-04 M S Consealed HS-06-A

M S Consealed HS-06-A M S Consealed HS-06-B

M S Consealed HS-06-B M S S S Consealed HS-07

M S S S Consealed HS-07 Spring Type S S M S HS-08

Spring Type S S M S HS-08 Spring Type HS-09

Spring Type HS-09 L T M S S S HS-10

L T M S S S HS-10 S S Spring HS-11

S S Spring HS-11 Capsule-Type S S M S HS-12

Capsule-Type S S M S HS-12 L T M S S S HS-13

L T M S S S HS-13 Z-TYPE HS-13-Z

Z-TYPE HS-13-Z Poly Profile HS-25

Poly Profile HS-25 Poly 7048/4530 HS-26

Poly 7048/4530 HS-26 Poly 4048/ 2630 HS-50

Poly 4048/ 2630 HS-50 Poly 3048/ 1230 HS-51

Poly 3048/ 1230 HS-51 Poly 5070 HS-27

Poly 5070 HS-27 Poly 4849 HS-28

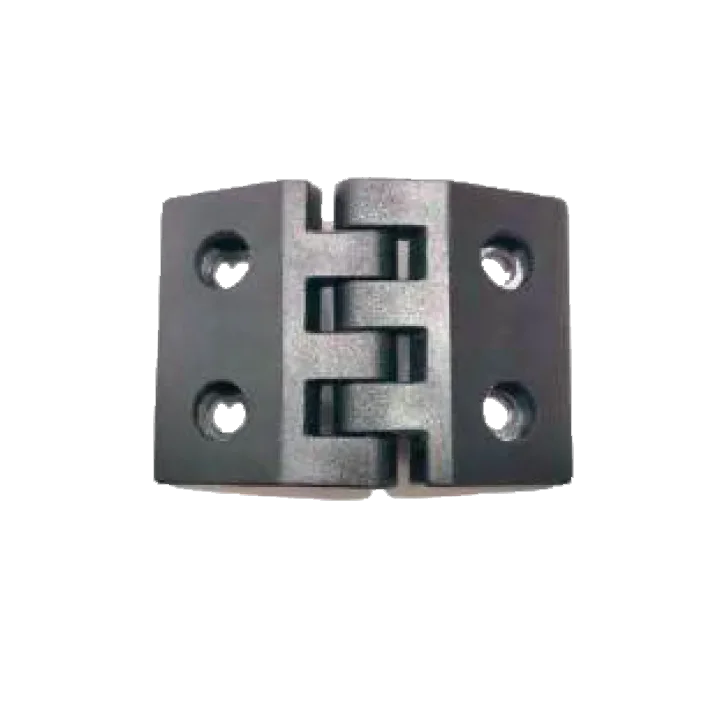

Poly 4849 HS-28 Die-Cast S.S. 4 Hole HS-30

Die-Cast S.S. 4 Hole HS-30 Die-Cast 50*63

Die-Cast 50*63 Die-Cast 50*76

Die-Cast 50*76 Die-Cast Bolted HS-31-A

Die-Cast Bolted HS-31-A Die-Cast HS-21-B

Die-Cast HS-21-B Die-Cast Rittal HS-32-A

Die-Cast Rittal HS-32-A Mild Steel Rittal HS-32-B

Mild Steel Rittal HS-32-B Polyamide 046 HS-33

Polyamide 046 HS-33 Poly 4 Hole

Poly 4 Hole M.S.& S.S. Hinges HS-38

M.S.& S.S. Hinges HS-38 Die Cast Hinges HS-62

Die Cast Hinges HS-62 M.S. Hinges HS-37

M.S. Hinges HS-37 MS & S.S. Hinges HS-35

MS & S.S. Hinges HS-35 S.S. Lift Off Hinges

S.S. Lift Off Hinges S.S. Butt Hinges HS-40-B

S.S. Butt Hinges HS-40-B M.S.& S.S. Hinges HS-41

M.S.& S.S. Hinges HS-41 Conveyor Guide

Conveyor Guide Conveyor Clamps

Conveyor Clamps Support Base CR-201

Support Base CR-201 Support Base CR-202

Support Base CR-202 Support Base CR-203

Support Base CR-203 Drip Tray Supports CR.252

Drip Tray Supports CR.252 Fixing Washer CR.338

Fixing Washer CR.338 Clamp For Sensor CR.341

Clamp For Sensor CR.341 Connecting Joints CR.501

Connecting Joints CR.501 Support Head CR-502-A

Support Head CR-502-A Support Head CR-502-B

Support Head CR-502-B Side Mounting Bracket CR.513

Side Mounting Bracket CR.513 Round Tube Ends CR.708

Round Tube Ends CR.708 Square Tube Ends CR.710

Square Tube Ends CR.710